T Series

3-6 [kW]

Max Diameter

240/350 [mm]

Max Tube Weight

300/600 [kg]

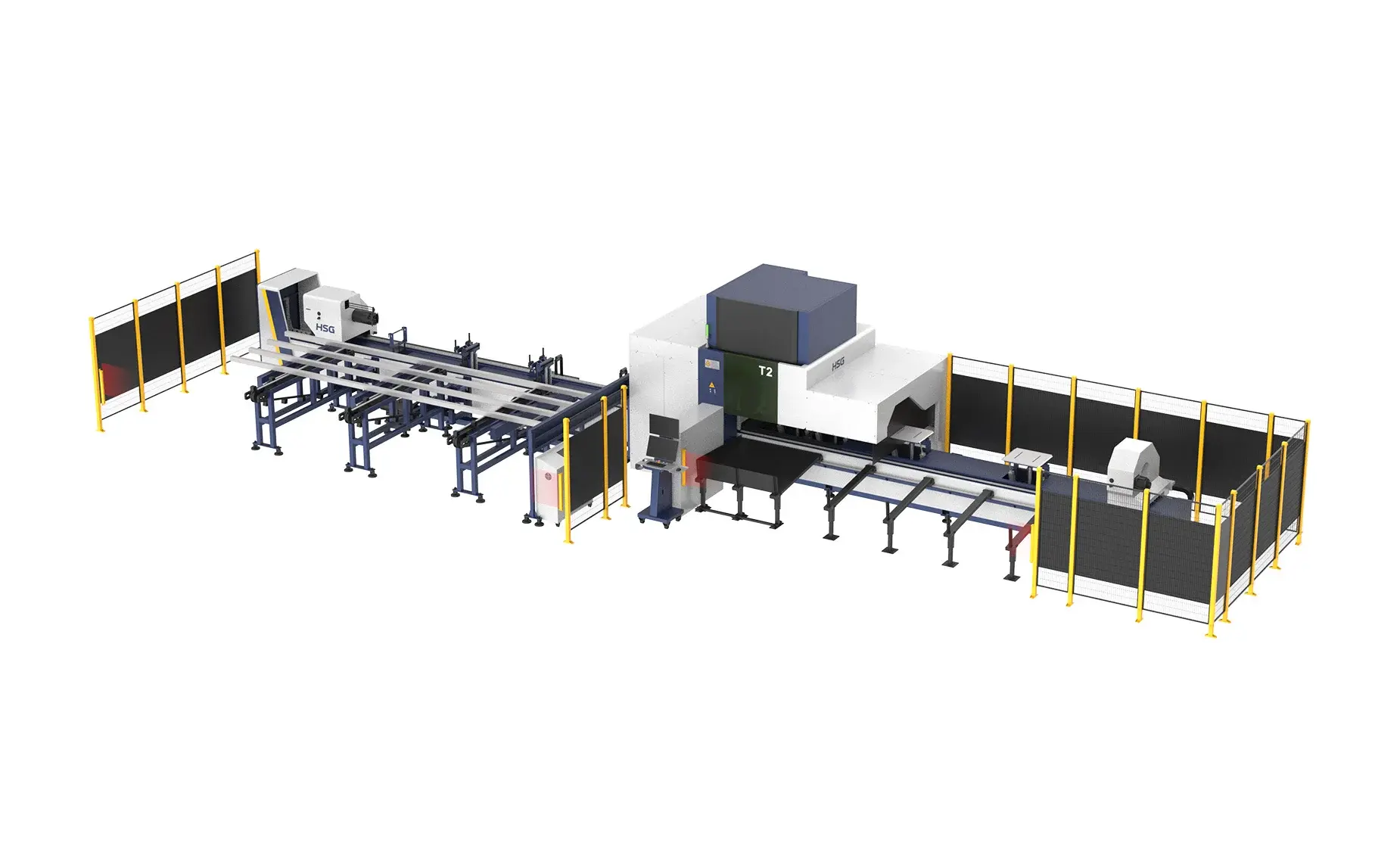

Reliable 3-Chuck Cutting for Mid-size Tube Solutions

OVERVIEW

Engineered in Japan

Reliable 3-Chuck Cutting for Mid-Size Tubes

ADVANCED EFFICIENCY AND COST SAVINGS

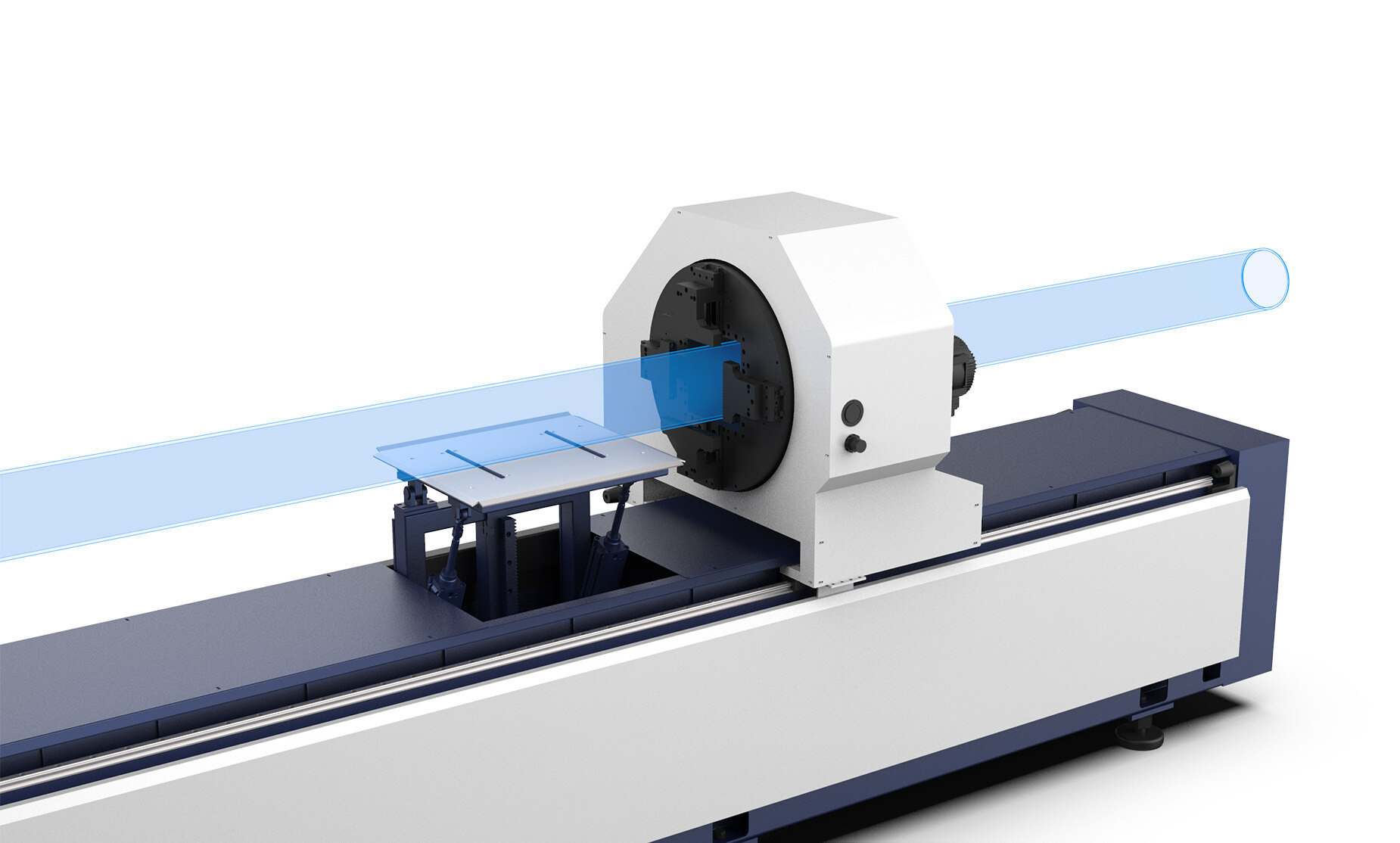

Full-Length Tube Loading and Unloading

The hollow chuck design allows tubes to pass through effortlessly, enabling the loading and unloading of entire tubes. This design increases the maximum tube length capacity, with automatic blanking lengths reaching up to 6m.

Zero Tail Cutting

The chuck’s forward and backward movement automatically adjusts the tube’s position, achieving zero tailings during cutting. This maximizes tube utilization and reduces material costs.

ENHANCED CUTTING PRECISION AND

SEAMLESS HANDLING

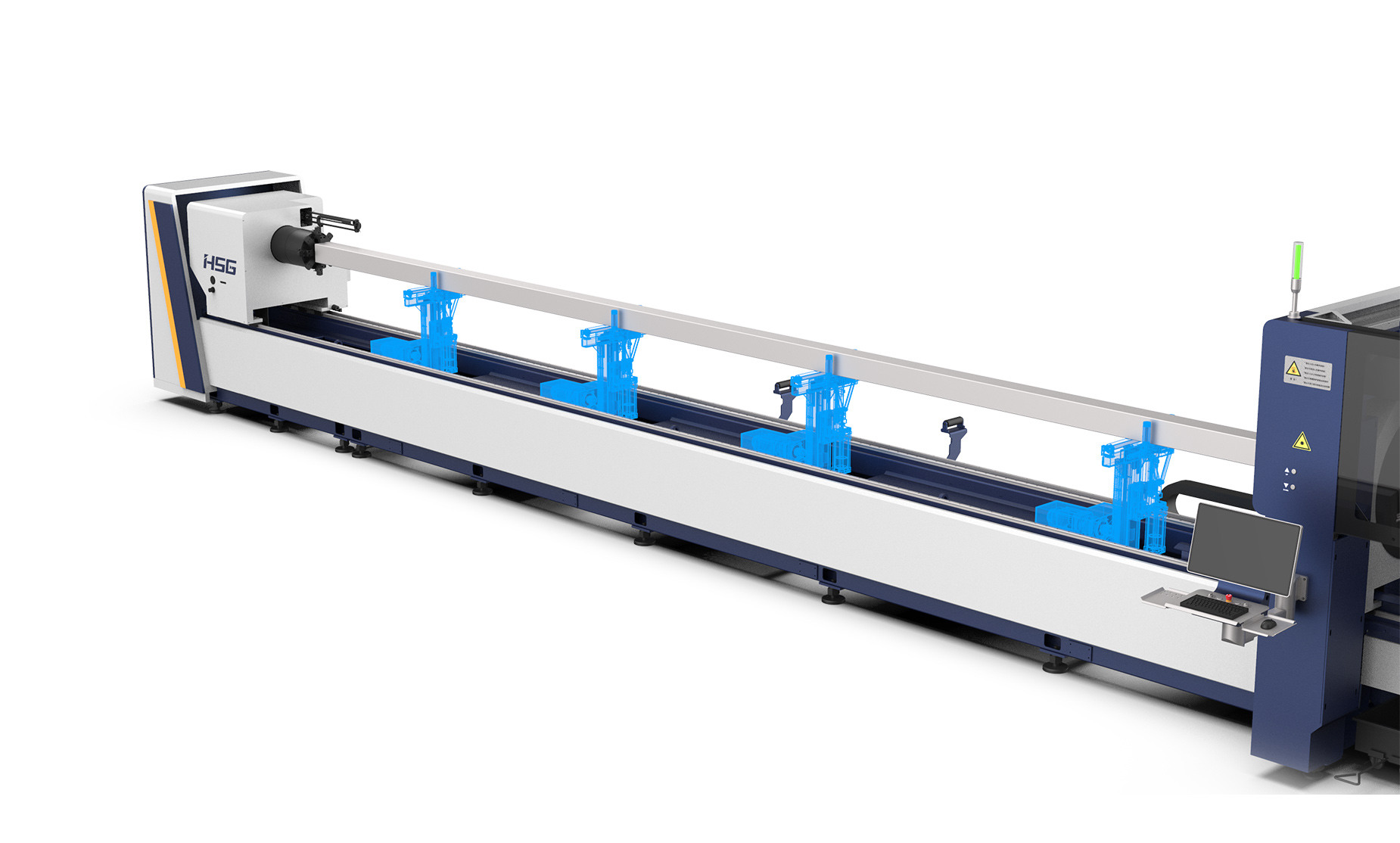

Independent Follow-Up Support on the Loading Lathe

The 7-meter-long loading lathe bed is equipped with four highly sensitive, independent servo follow-up support components. These components provide robust support during tube rotation cutting, ensuring precision and stability.

Independent Follow-Up Support on the Unloading Lathe

The 6-meter unloading lathe bed features four highly sensitive, independent servo follow-up support components. Combined with the system’s intelligent cutting mode, this setup enables seamless, stepless unloading of workpieces up to 6 meters long, enhancing efficiency and accuracy.

BOOST PROCESSING AUTOMATION WITH PRECISION

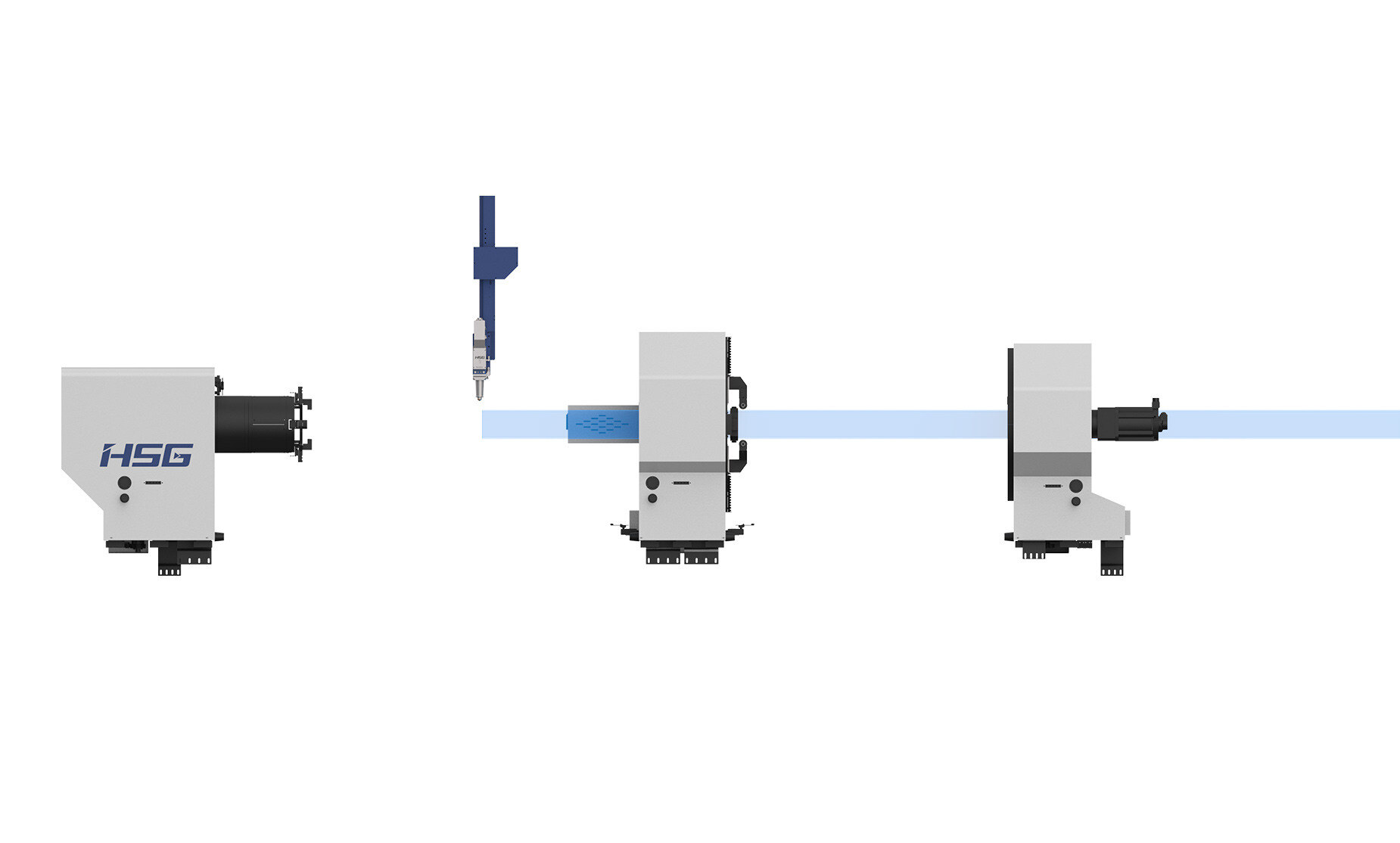

Photoelectric Loading Detection

Advanced photoelectric detection accurately identifies the size, shape, and position of each tube, enabling precise clamping by the chuck. Through real-time monitoring and feedback, the system dynamically adjusts equipment status, ensuring stable, reliable, and fully automated processing.

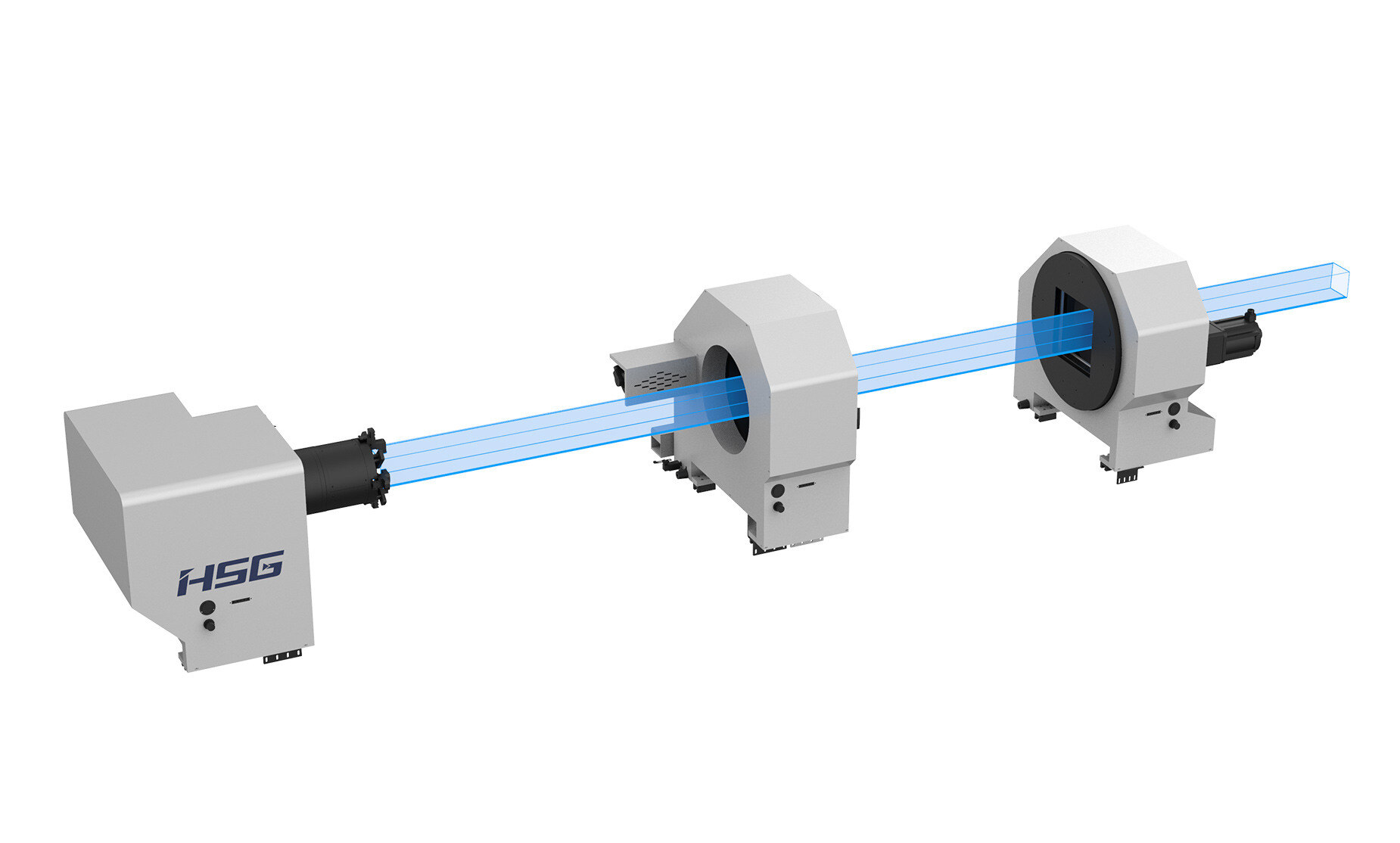

REINFORCE CHUCK LOAD-BEARING CAPACITY

Durable Dual Front, Single Rear Chuck Structure

The durable dual-front, single-rear chuck design provides comprehensive clamping and support for tubes, greatly enhancing load-bearing capacity. This design ensures a smoother cutting process while delivering outstanding cutting precision.

SIMPLIFYING OPERATIONS WITH

VERSATILE FUNCTIONS

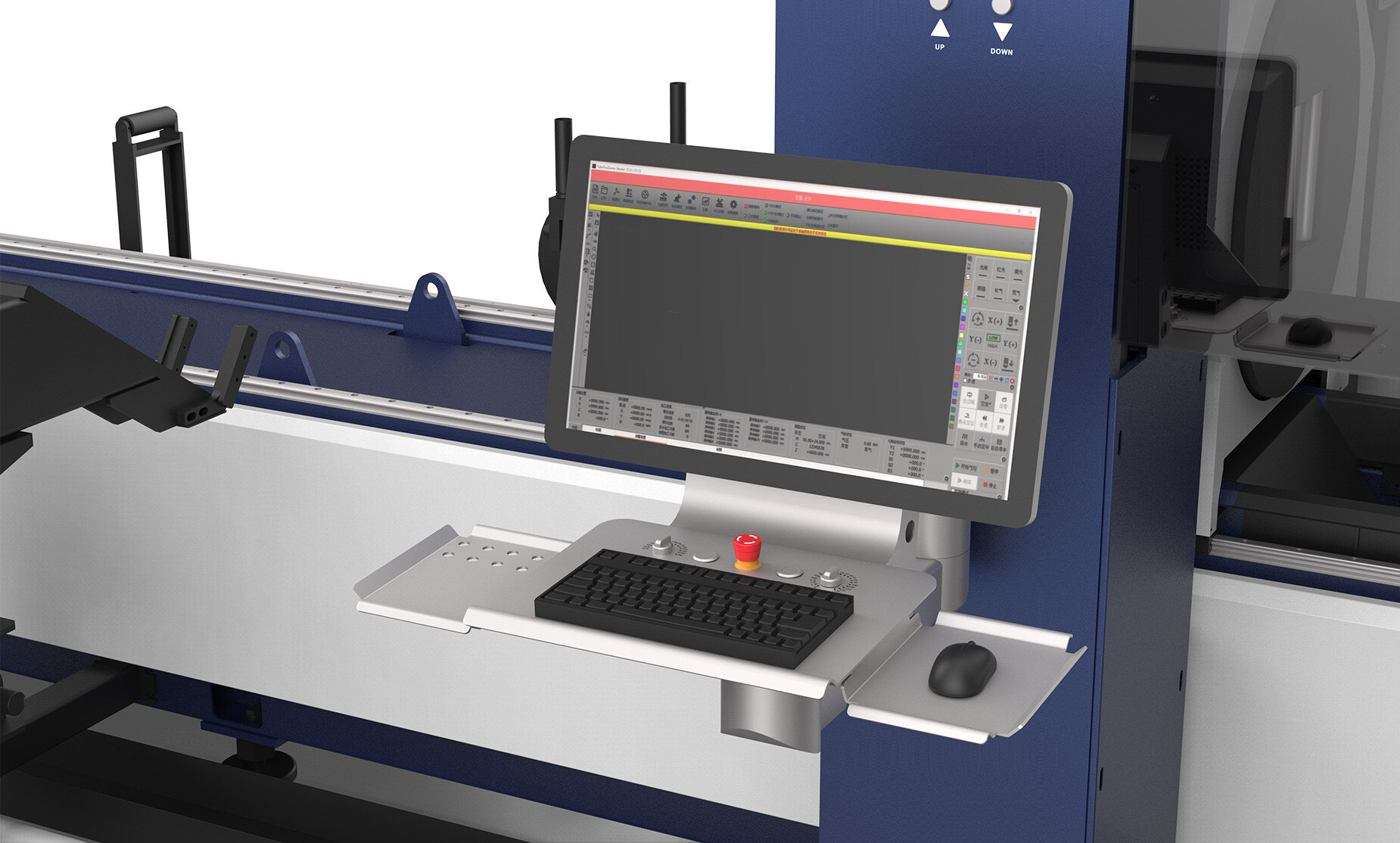

HSG-X10000 Bus Cutting System

Featuring the HSG-X10000 bus cutting system, this solution offers a wide range of auxiliary functions tailored for pipe cutting applications, covering the most commonly used operations. Its user-friendly interface ensures easy operation, meeting diverse cutting needs while enhancing production efficiency and processing quality.

T Technical Specifications

For more details, feel free to reach out to us!

|

Model

|

T2

|

T3 |

|

Power

|

3-6kW

|

3-6kW

|

|

Tube Range in Diameter

|

Φ20-240mm

|

Φ40-350mm |

|

Cutting Capacity of Square Tube

|

□20×20mm- □240×240mm

|

□40×40mm- □350×350mm

|

|

Weight of Single Tube

|

300kg

|

600kg

|

|

Chuck Speed

|

100 rpm

|

80 rpm

|

|

Max Linkage Speed

|

100m/min |

80m/min |

|

Maximum Acceleration

|

1.0G

|

0.8G

|

TALK WITH OUR EXPERT OR REQUEST A QUOTE