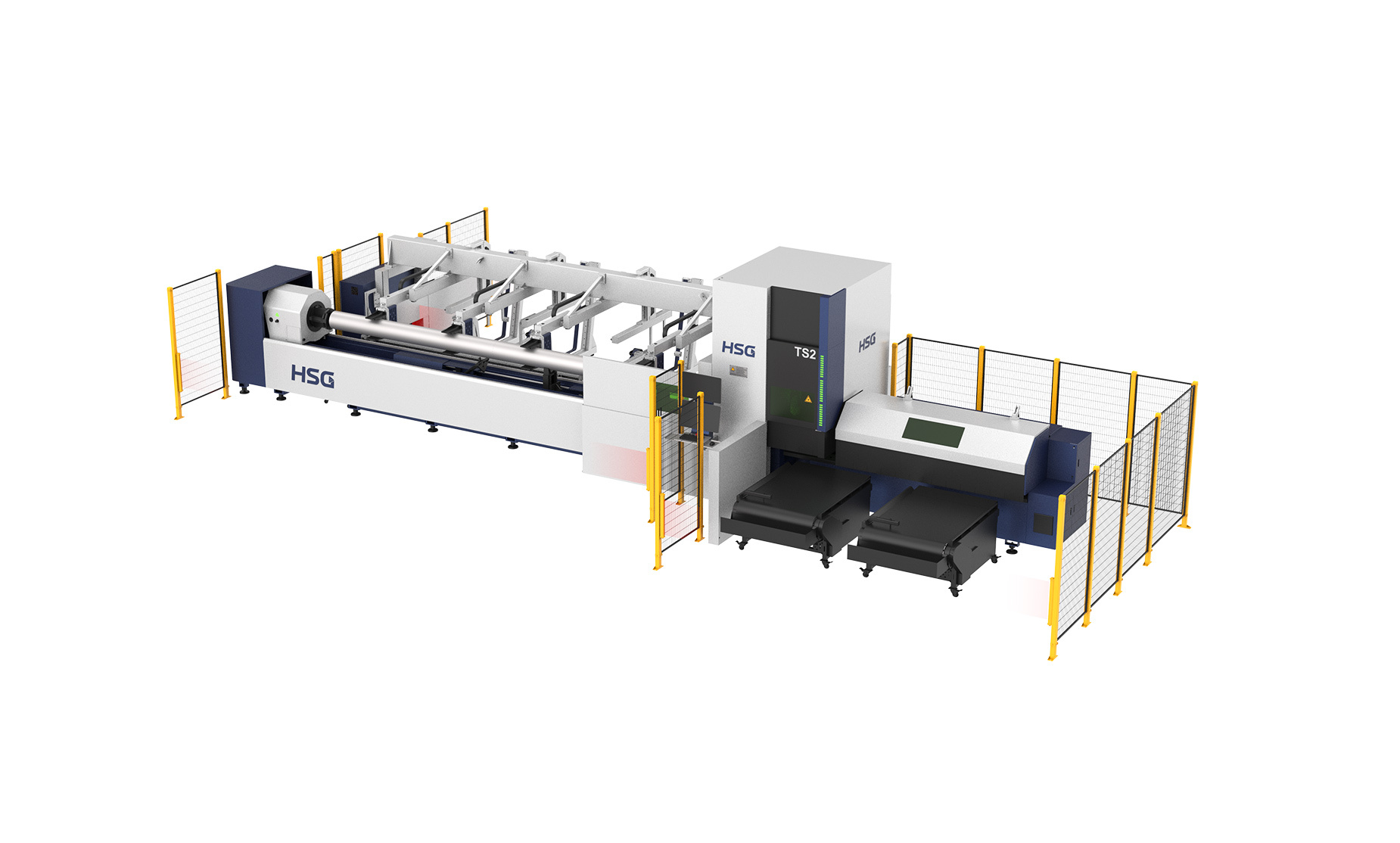

TS2 Series

3-6 [kW]

Max Tube Weight

300kg

Your Secret Weapon for Tube Laser Cutting

Fast Cutting

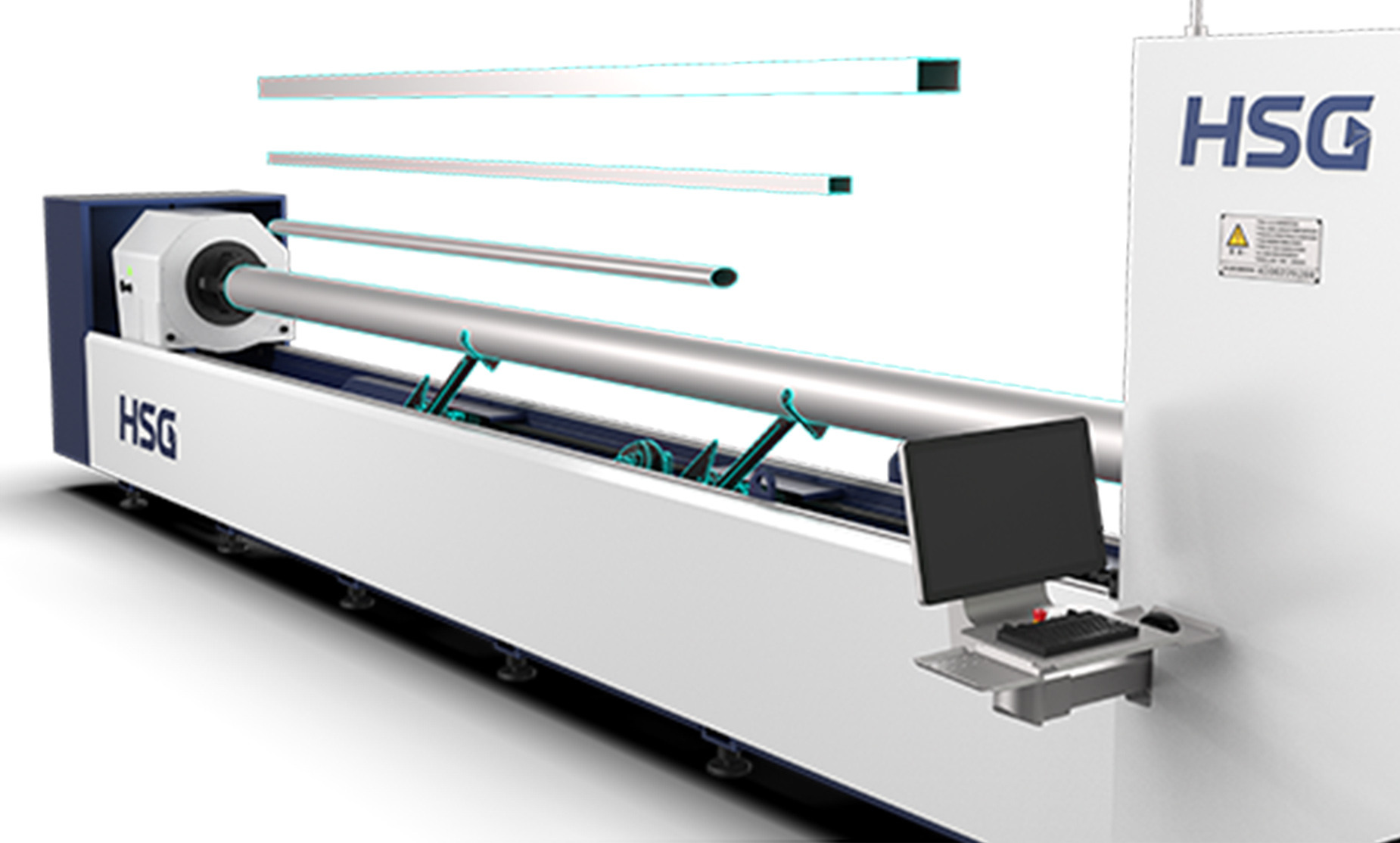

Dynamic Chuck

At the same time, the rear chuck is equipped with air and dust suction functions, making the workpiece tube cleaner and maintaining a clean processing environment.

Capability of Multiple Tube Processing

Standard configuration includes two clamps for tubes and profiles, capable of processing tubes with a weight of ≤ 300kg (661 lbs) and a diameter range of 12-273mm (0.47''-10.75'') for round tubes. It also supports cutting profiles such as channel steel, angle steel, and I-beams.

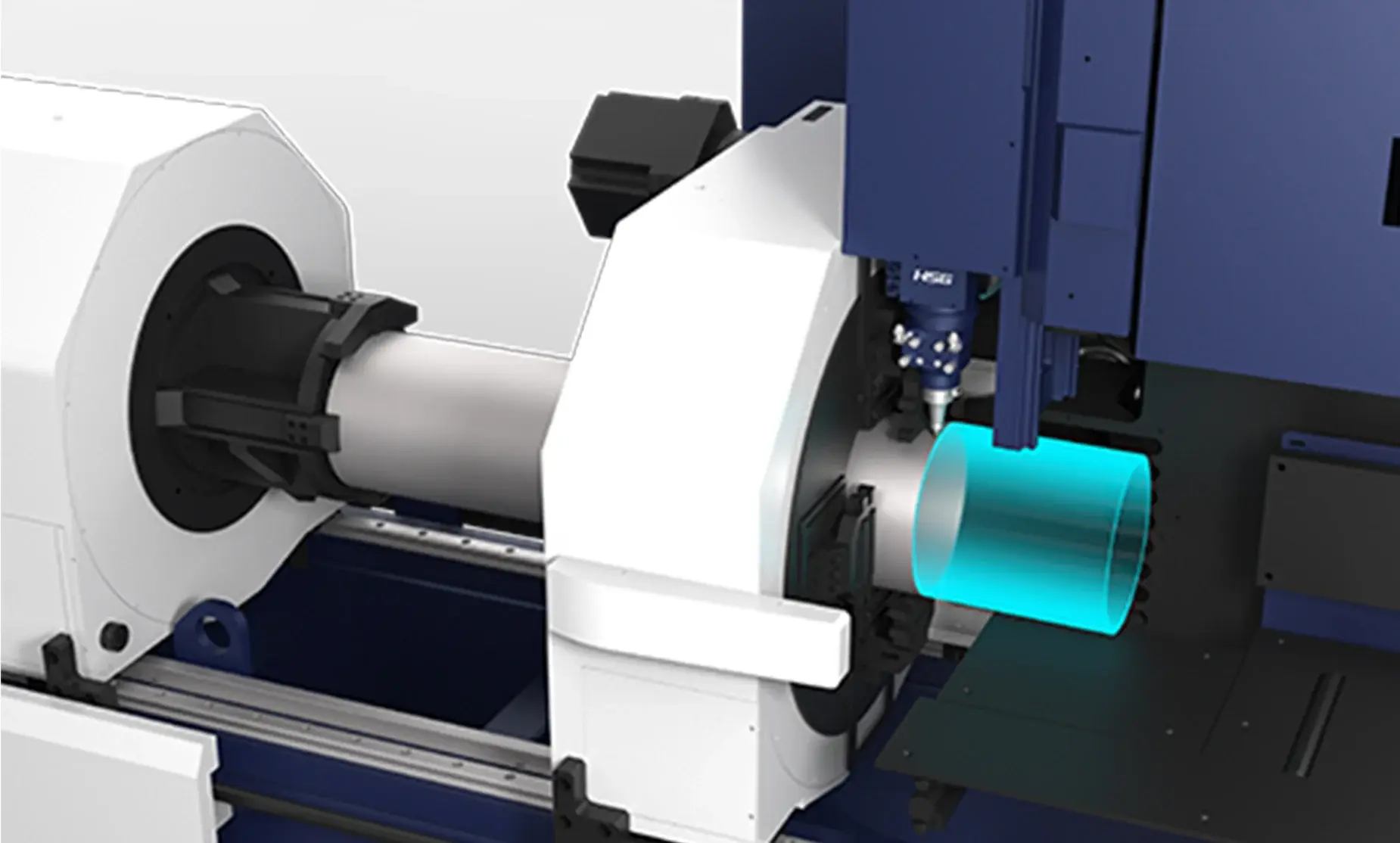

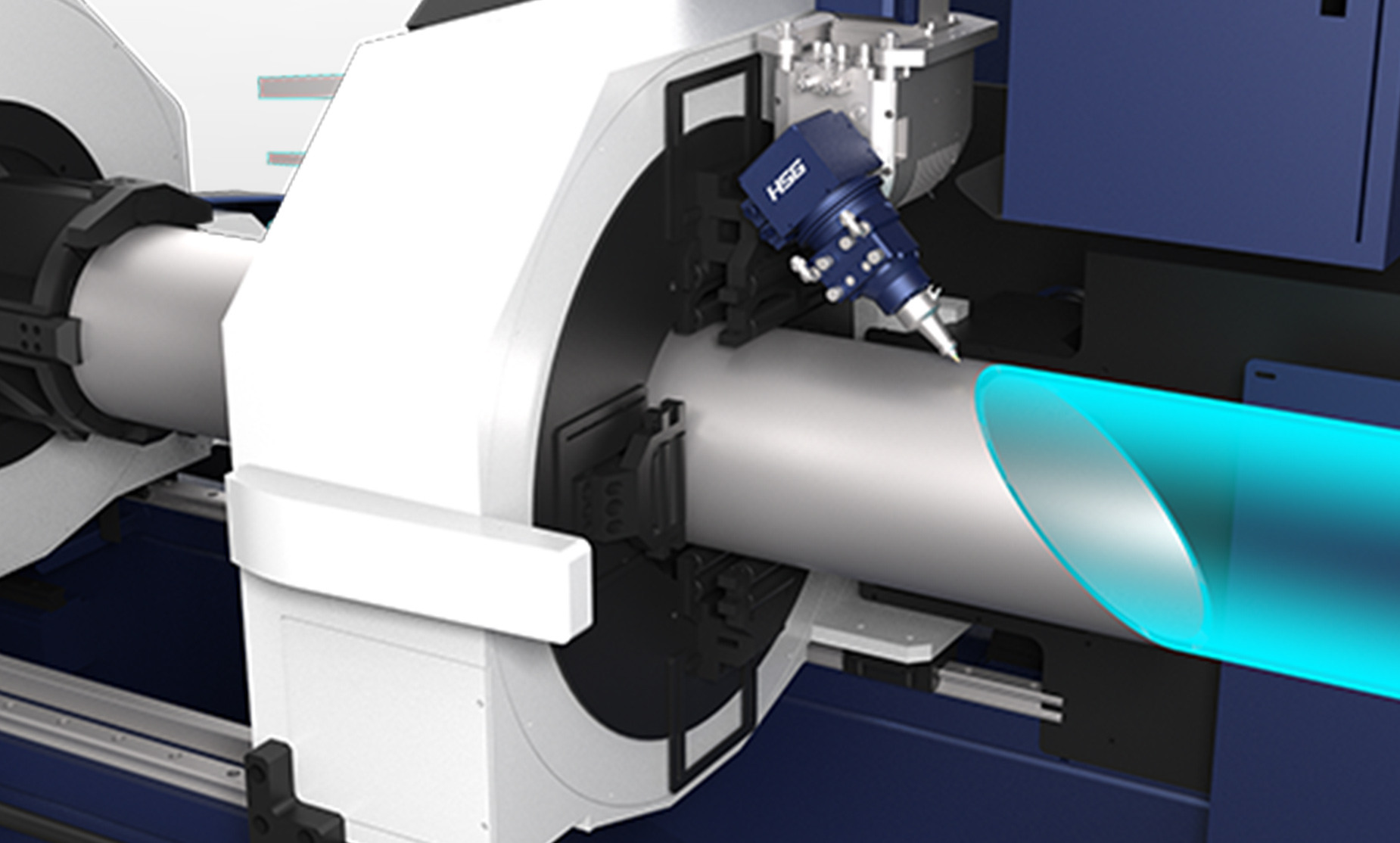

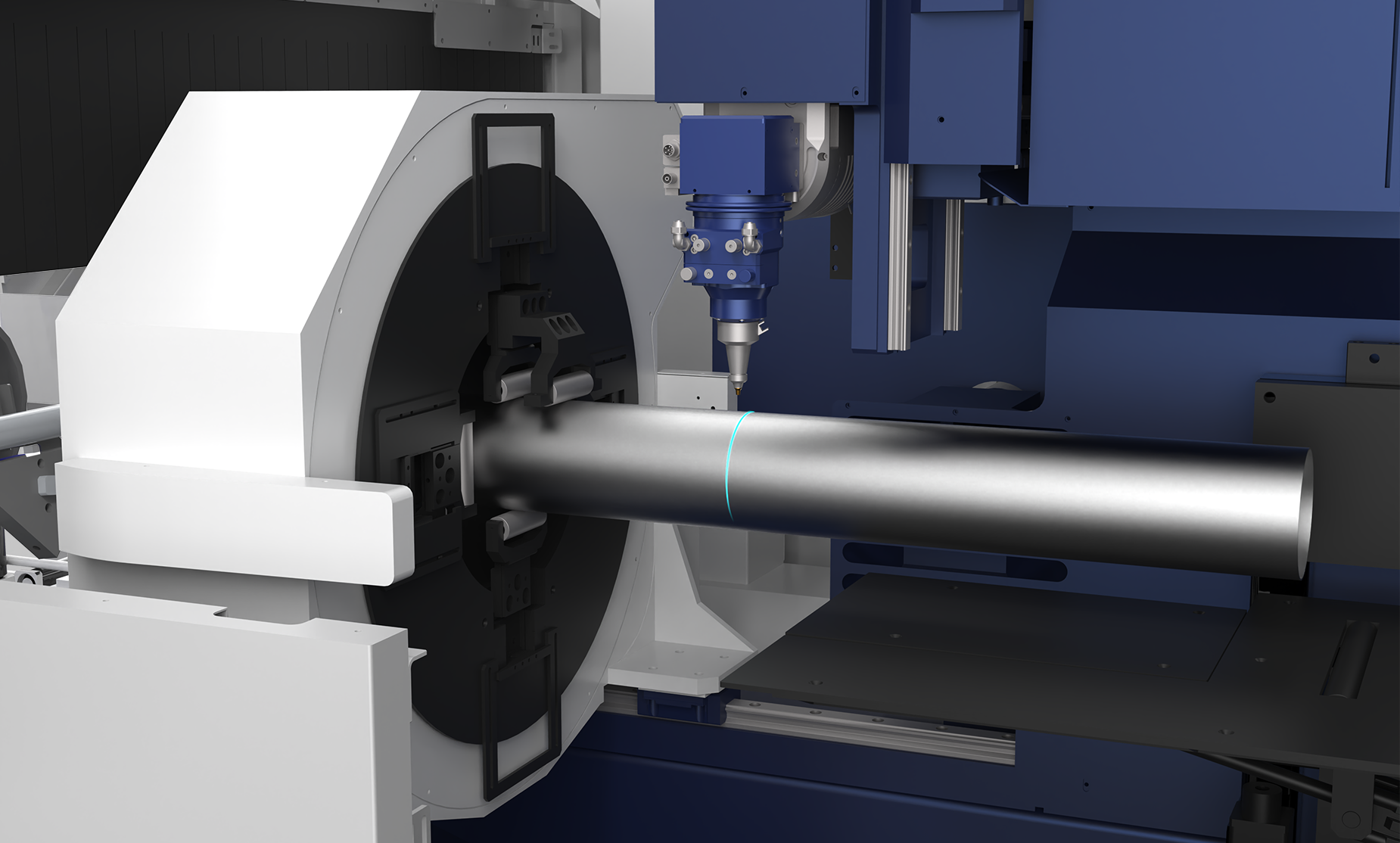

HSG 3D Cutting Technologies (Optional)

HSG-LA4 tube bevel cutting head can be optionally selected to achieve 0-45 ° tube bevel cutting.

Dynamic Unloading

Efficient Automatic Loading Within 25s(Optional)

Optional fully automatic loading. The loading time can be as short as 25 seconds, improving processing efficiency.

Dynamic Support

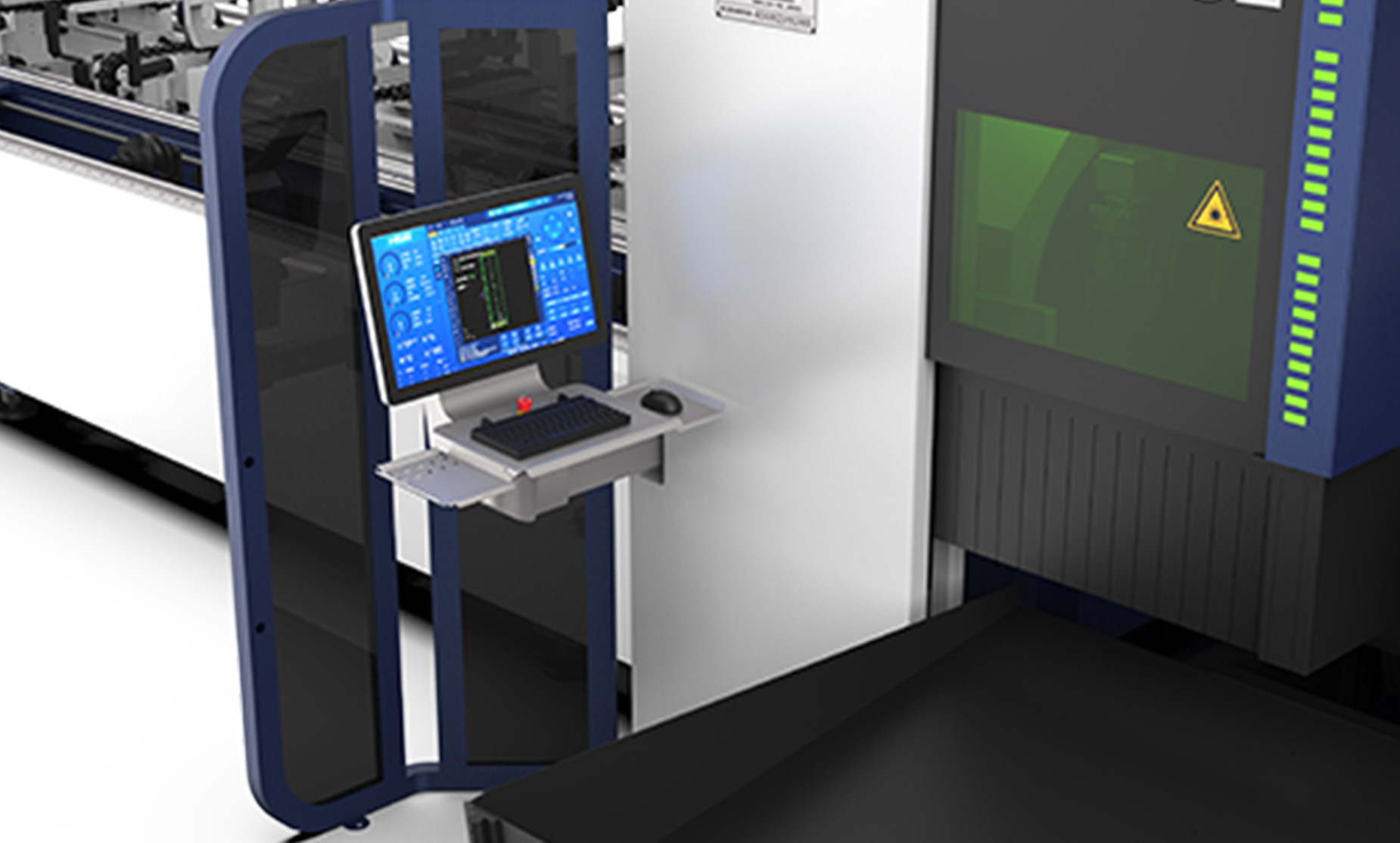

HSG-X Intelligent Bus Operating System

Clear interface is convenient for users operating and shows cutting data in real time to save time and costs.

A number of core functions are shown centrally on the interface to reduce operating steps and users can easily learn to operate.

3 in 1: Cutting+Drilling+Tapping(Optional)

Integrated laser cutting, hot melt drilling and tapping, for molding at once to reduce processing processes, save labor, greatly shorten processing time and improve production efficiency.

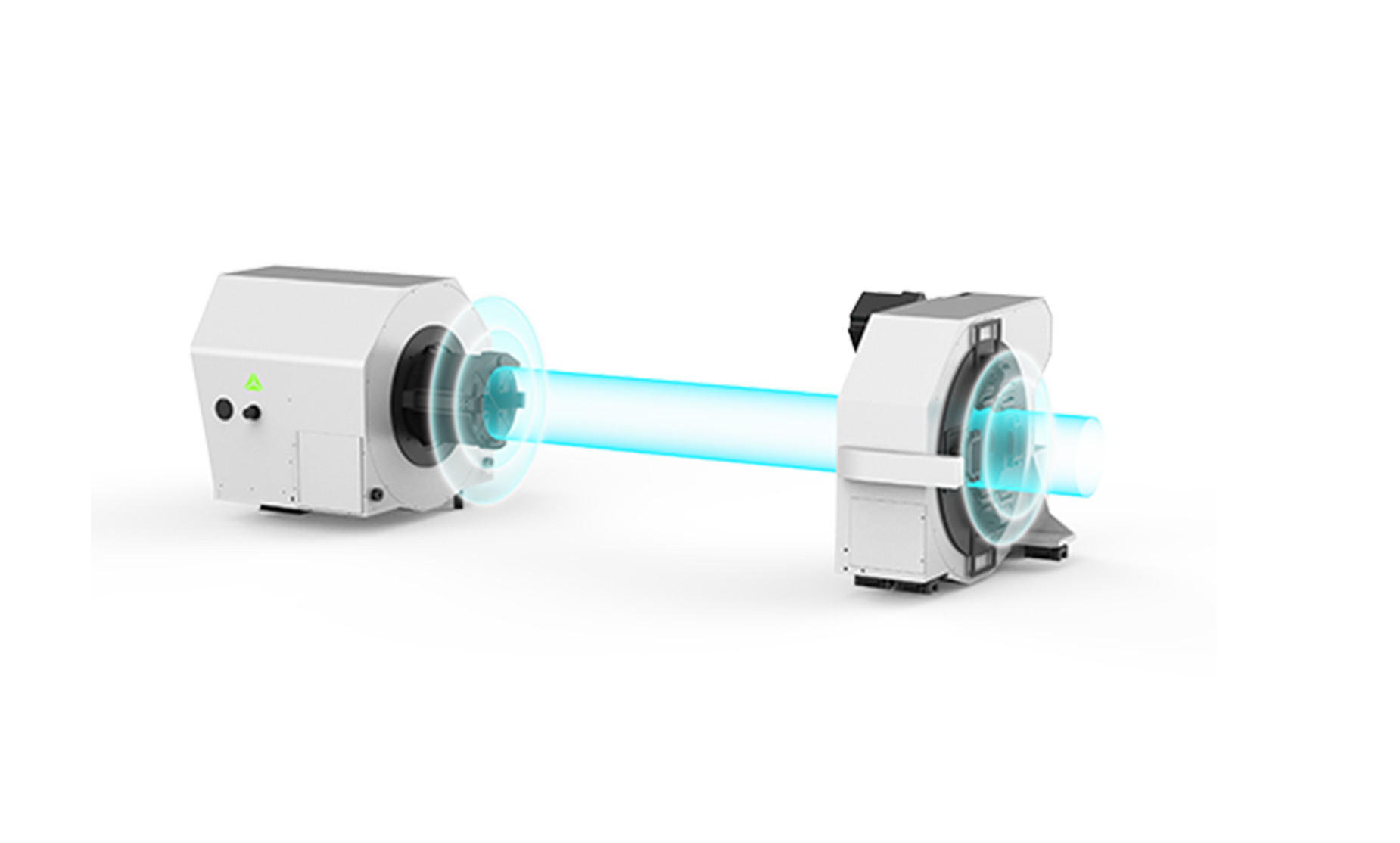

Dynamic Seamline Inner Weld Detection (Optional)

Accurately identifies weld seams from inside the tube, preventing recognition errors caused by external rust or polishing, and reducing scrap rates.

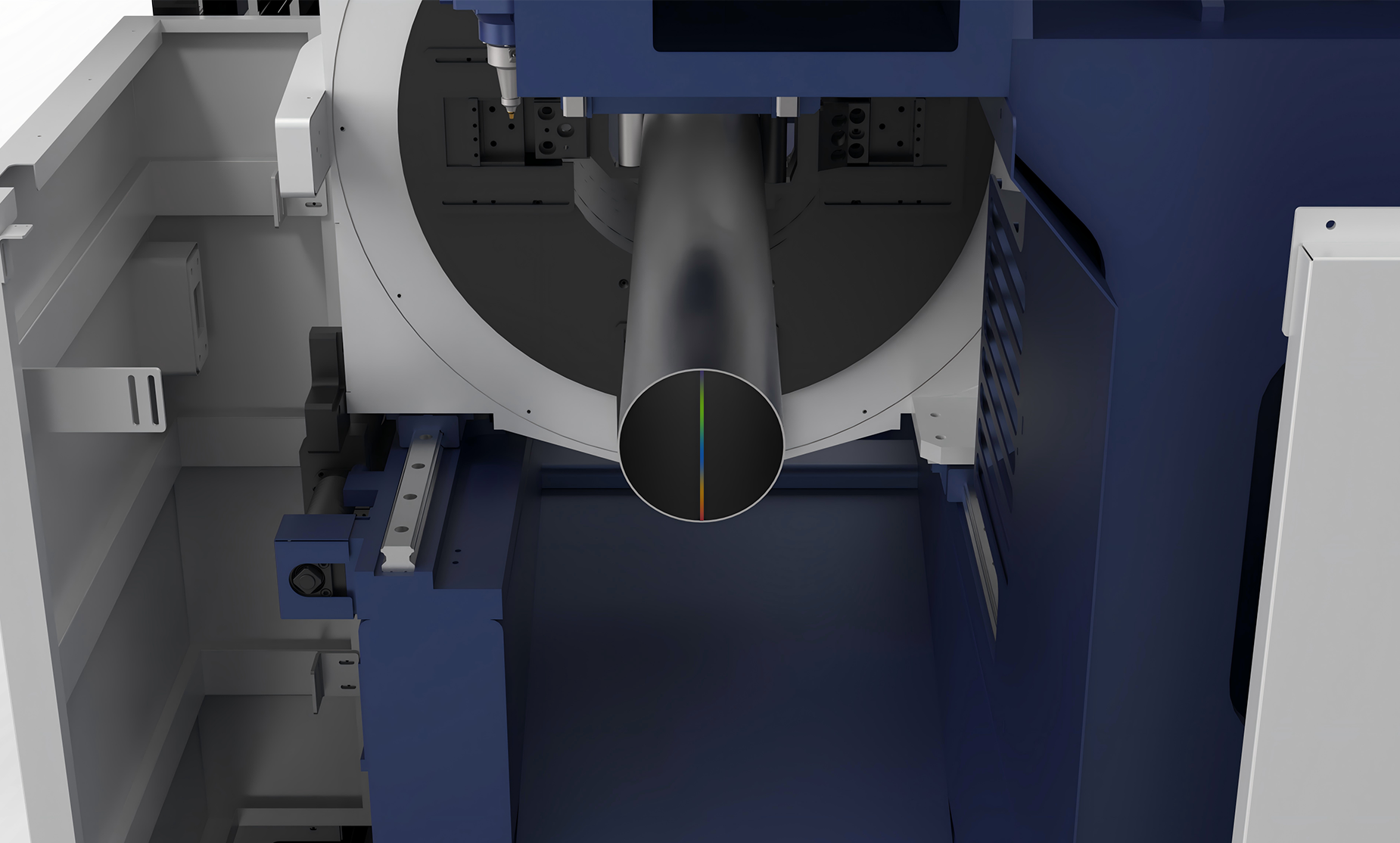

Dynamic Line-Scan Auto Centering (Optional)

Uses blue light to scan the tube, automatically locating the tube center to enhance cutting accuracy.

TS2 Technical Specifications

For more details, feel free to reach out to us!

| Model | TS2 | TS2-90 | ||||

|

Power

|

3-6kW

|

3-6kW

|

||||

|

Cutting Capacity of Round Tube

|

φ12-273mm

|

φ12-273mm

|

||||

|

Cutting Capacity of Square Tube

|

□12×12mm-□220×220mm

|

□12×12mm-□220×220mm

|

||||

|

Range of Tube Length

|

1-6.5m

|

1-9.2m

|

||||

|

Range of Unloading Length

|

3m(standard) / 4.5m(optional)

|

4.5m(standard) / 6.5m(optional)

|

||||

|

Weight of Single Tube

|

300kg

|

300kg

|

||||

|

Acceleration

|

1.4G

|

1.4G

|

||||

TALK WITH OUR EXPERT OR REQUEST A QUOTE