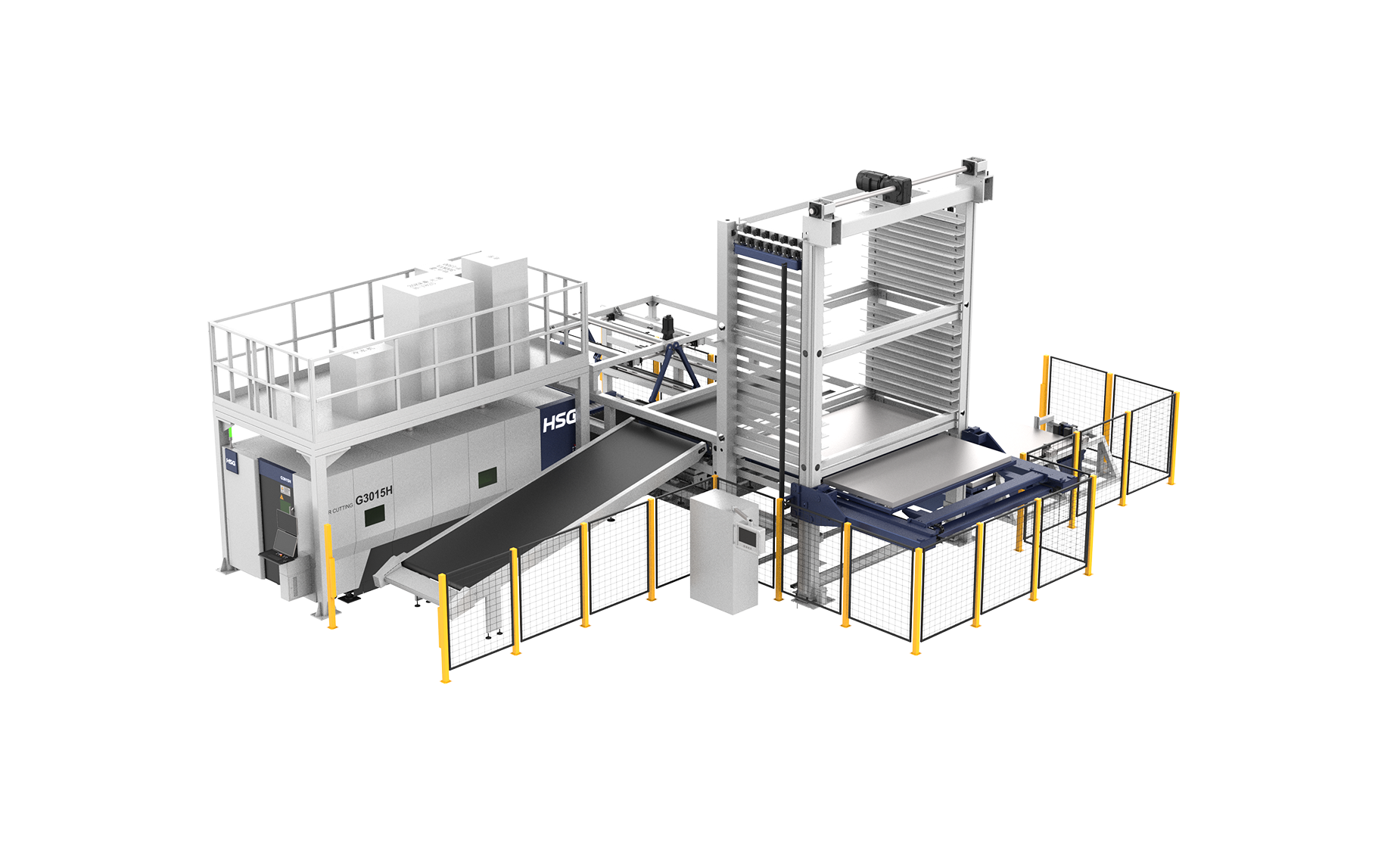

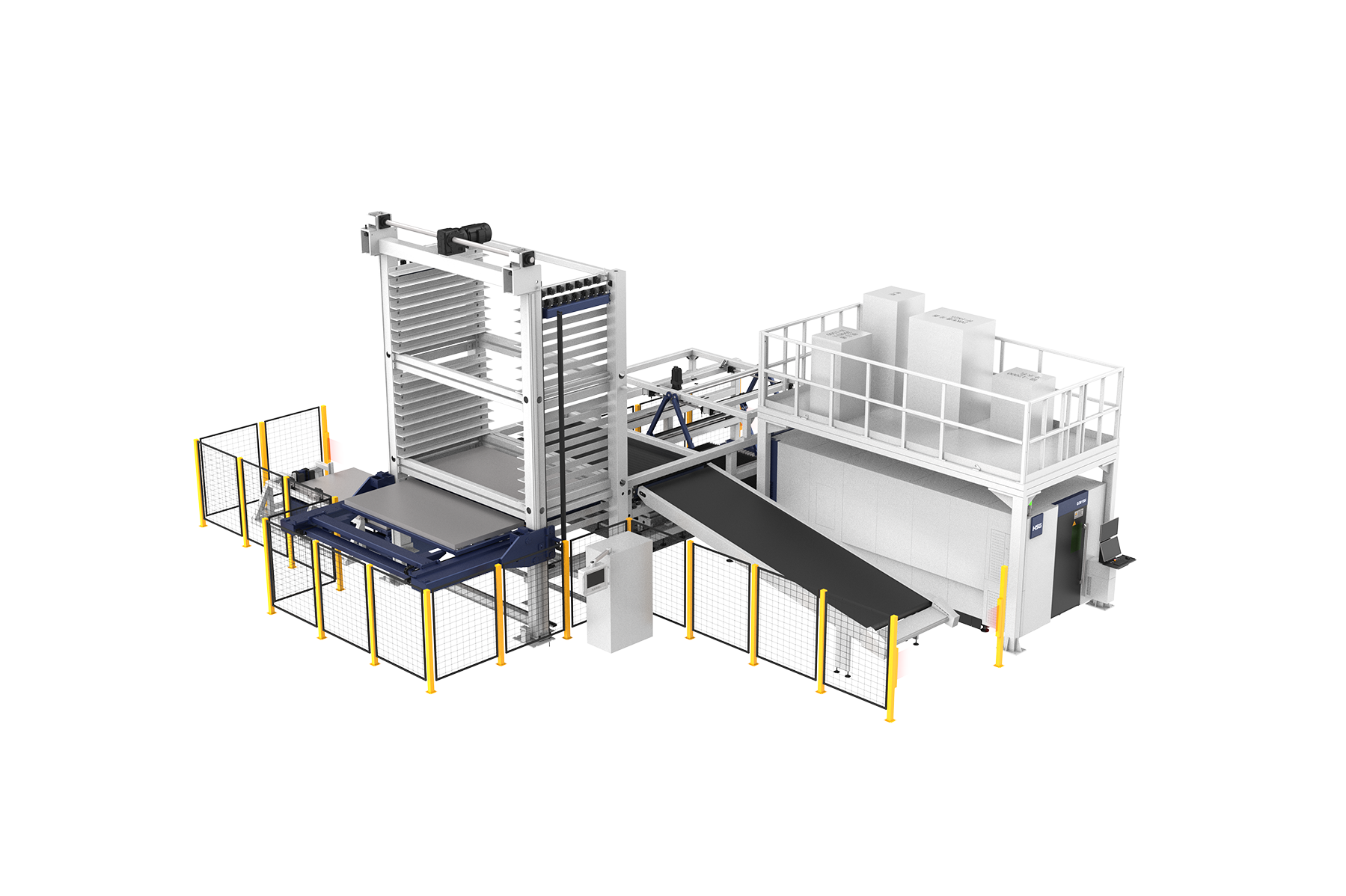

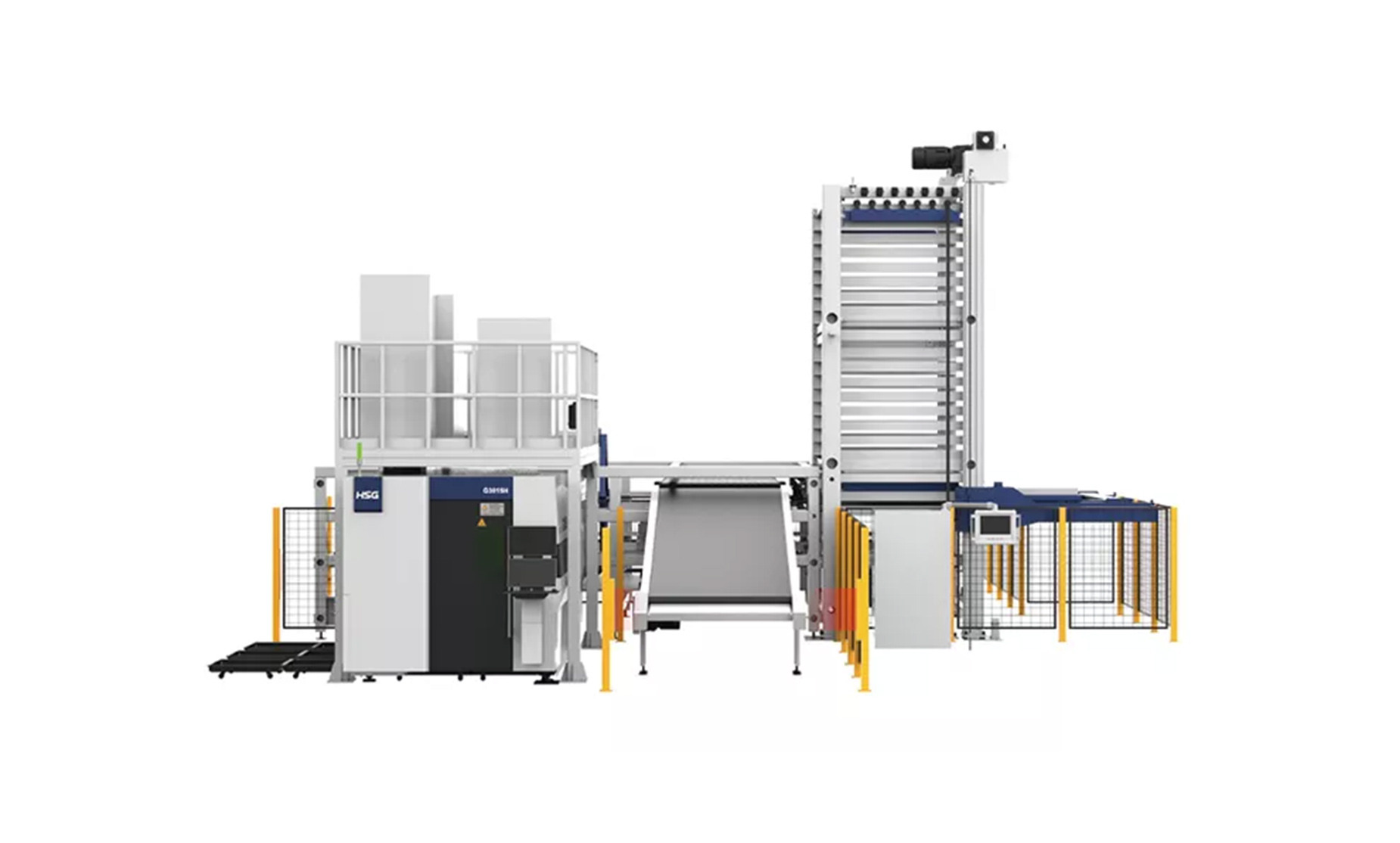

Store Pro

Premium Intelligent Laser Automatic System

Your Challenge – Our Concern

• Hard to find labor, especially for the second or third shift.

• Limited plant height

• Low machine utilization and output per day

• Difficult to manage materials and finished goods

• Limited budget

The solution is designed to help you solve those bottlenecks for the highest output. With the STORE Pro, novices and advanced users alike benefit from an affordable and user-friendly automatic solution.

Your Challenge – Our Concern

• Hard to find labor, especially for the second or third shift.

• Limited plant height

• Low machine utilization and output per day

• Difficult to manage materials and finished goods

• Limited budget

The solution is designed to help you solve those bottlenecks for the highest output. With the STORE Pro, novices and advanced users alike benefit from an affordable and user-friendly automatic solution.

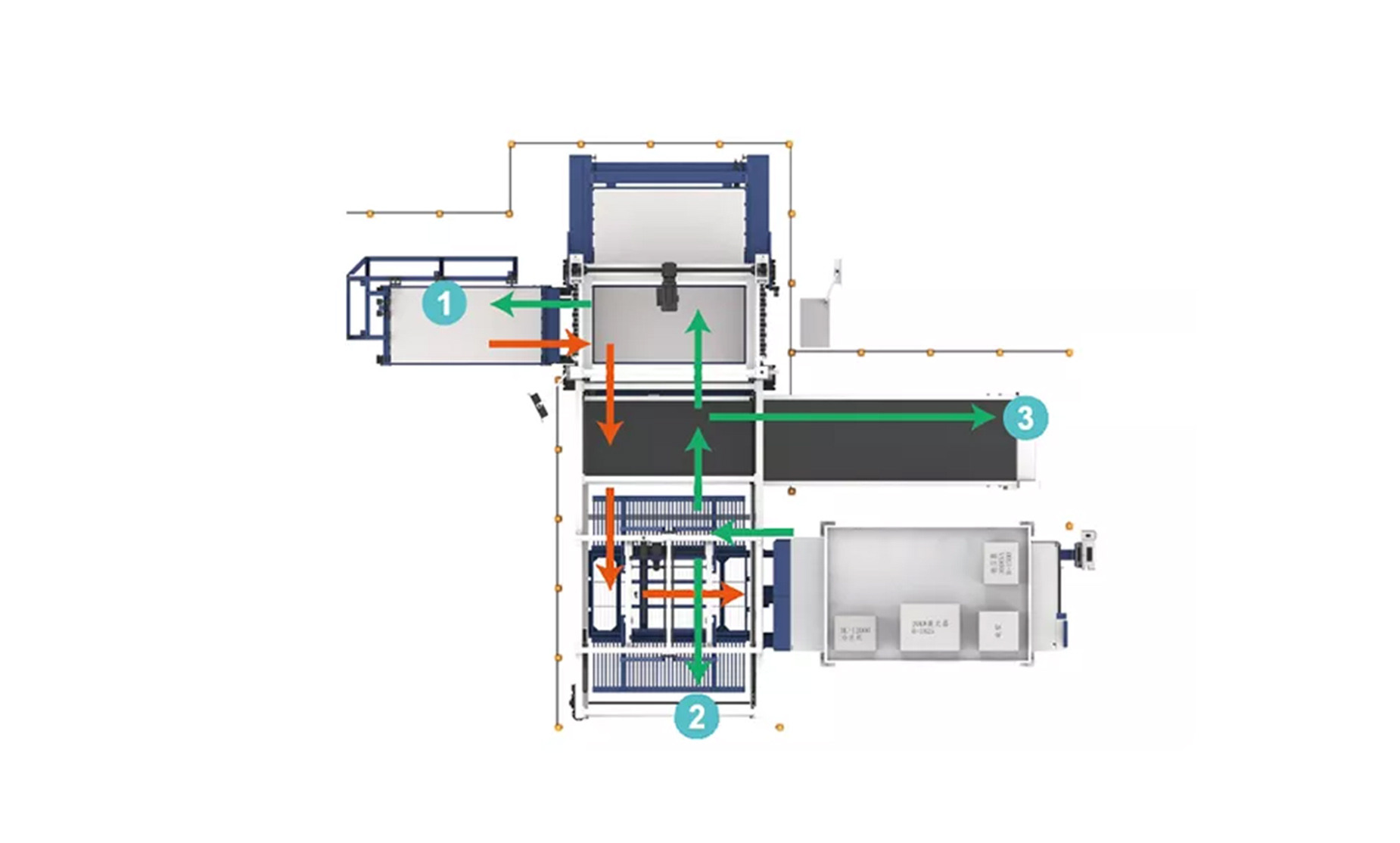

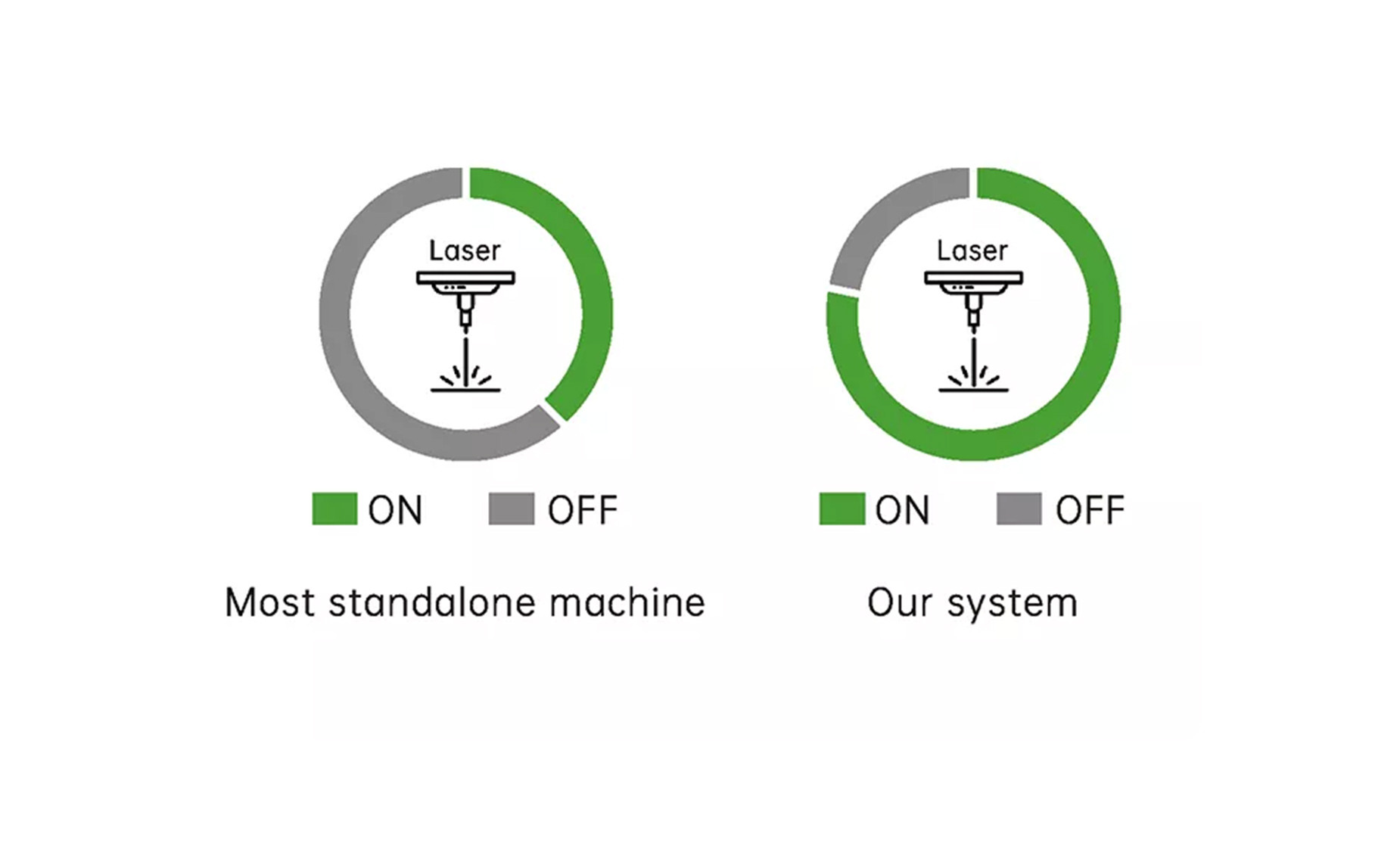

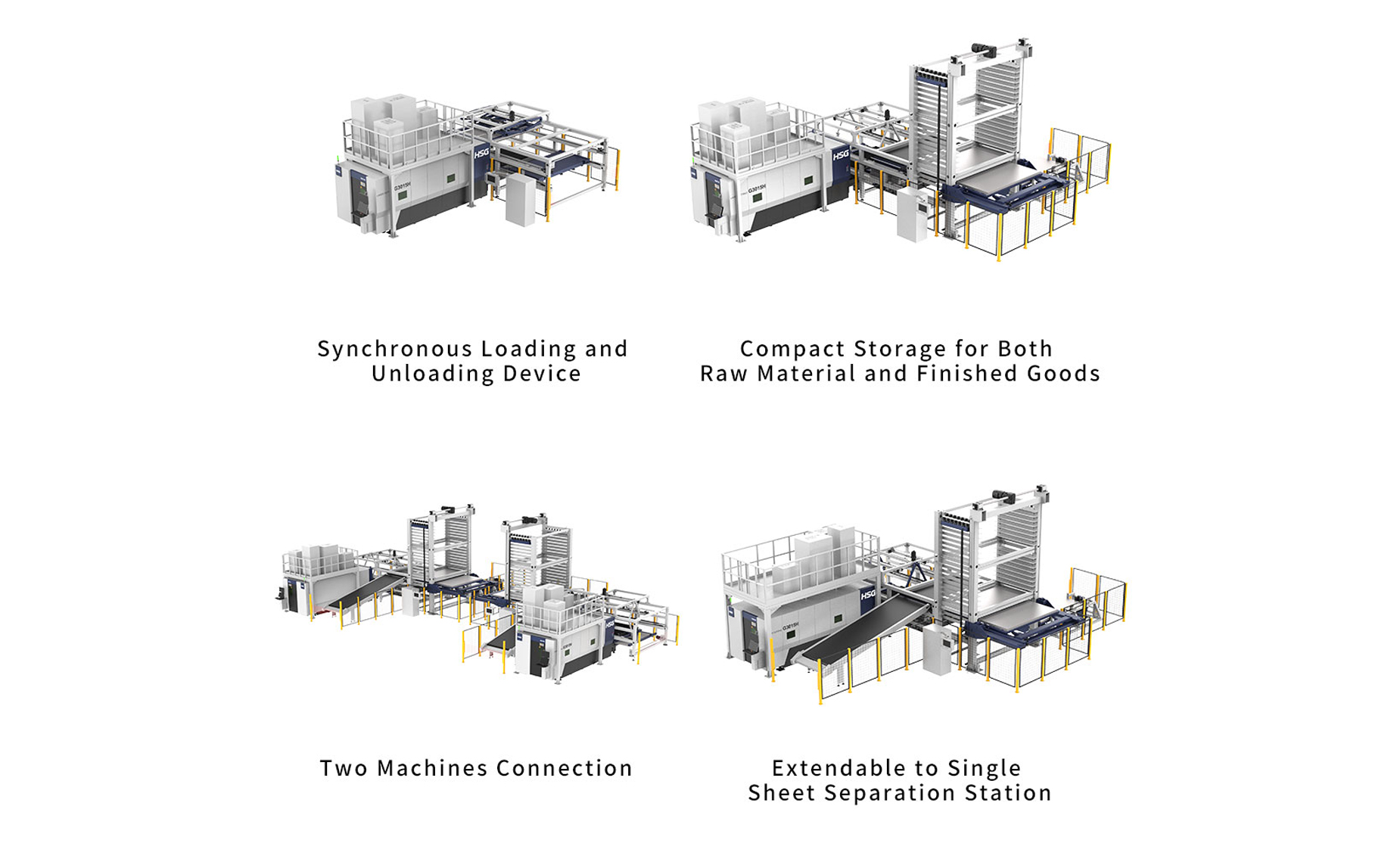

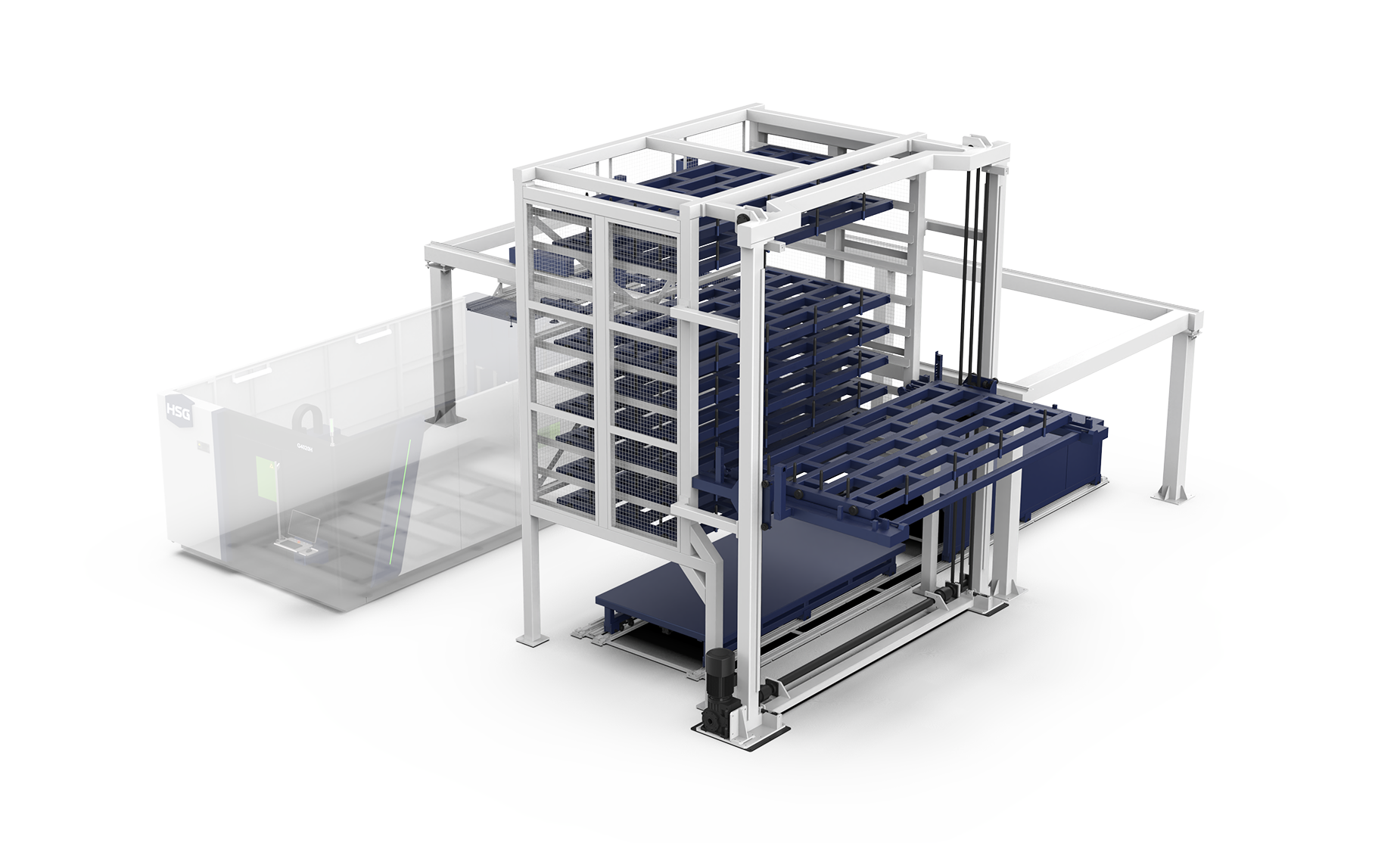

Optimized Machine Utilization Boost Your Output

Automation reduces waiting time for material handling by logistic staff, while our system makes the loading and unloading time even shorter by using synchronous processes. Your machine could be fully utilized, which enables you maximize your hourly output and save your money on another machine, additional space and operators.

70%+ Improved Space

Max. 10 positions per tower with a height of 4.4m.

Save Your Cost in Each Step

Our system could grow together with your business. The modular design enables a cost-effective extension of the automation system.

HSG Store Pro Technical Specifications

| Model | Store Pro 3015 | Store Pro 4020 |

|

Max./Min. Loading Sheet Size

|

3048×1524 mm (10' x 5')/1000×1000 mm (3.28' x 3.28')

|

4064×2032 mm (13.3' x 6.6') / 1000×1000 mm (3.28' x 3.28')

|

|

Max. Sheet Weight

|

600 kg (1322 Ibs) | 1200 kg (2645 Ibs) |

|

Tower Height (standard)

|

4400mm (14.4'), modular extension optional

|

4400mm (14.4'), modular extension optional

|

|

Max. Stacking Height Per Pallet

|

90mm (3.54'')/310mm (12.2'') | 90mm (3.54'') / 290mm (11.4'') |

|

Max. Loading Weight Per Pallet

|

3000 kg (6613 Ibs) | 5000 kg (11023 Ibs) |

TALK WITH OUR EXPERT OR REQUEST A QUOTE

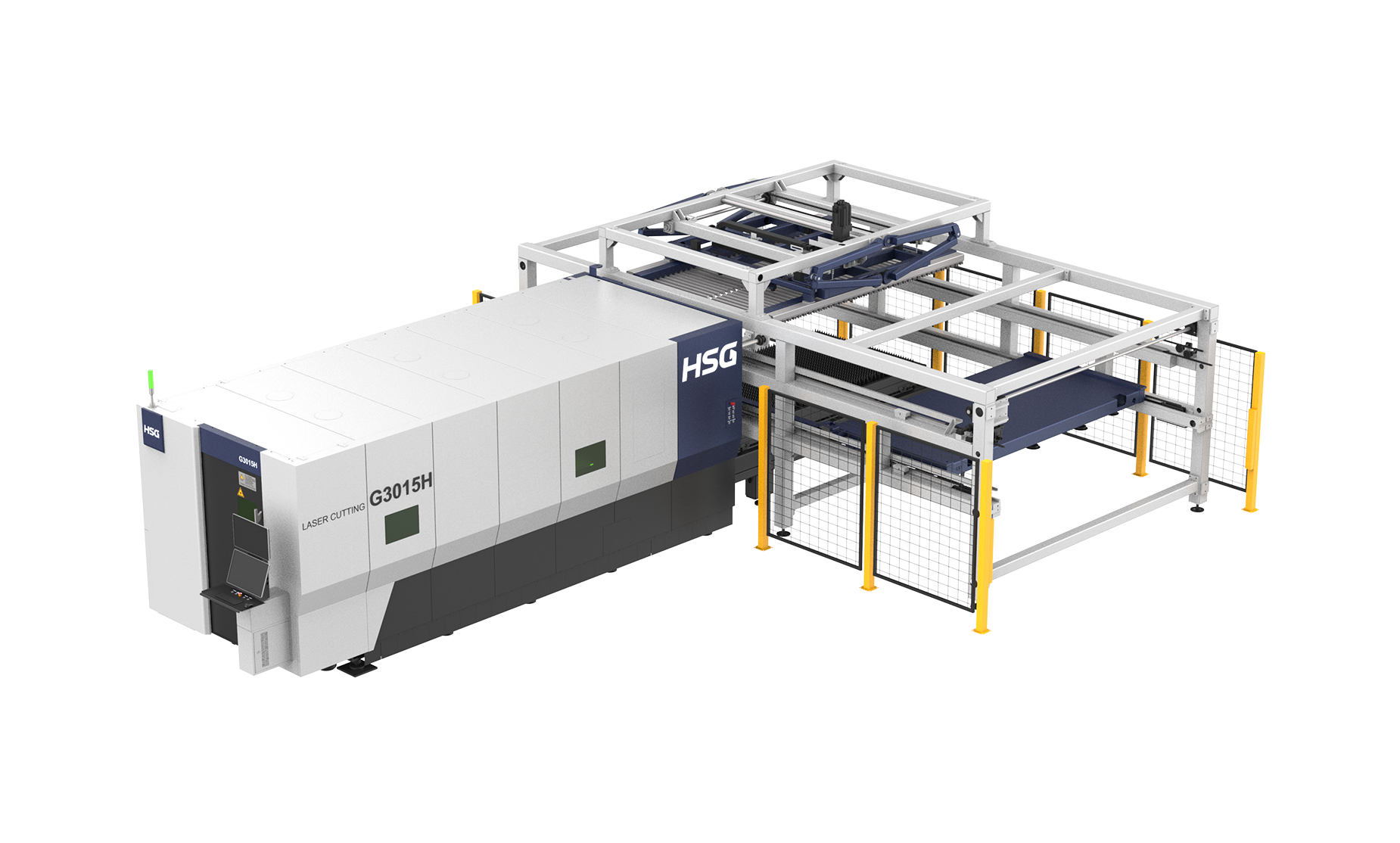

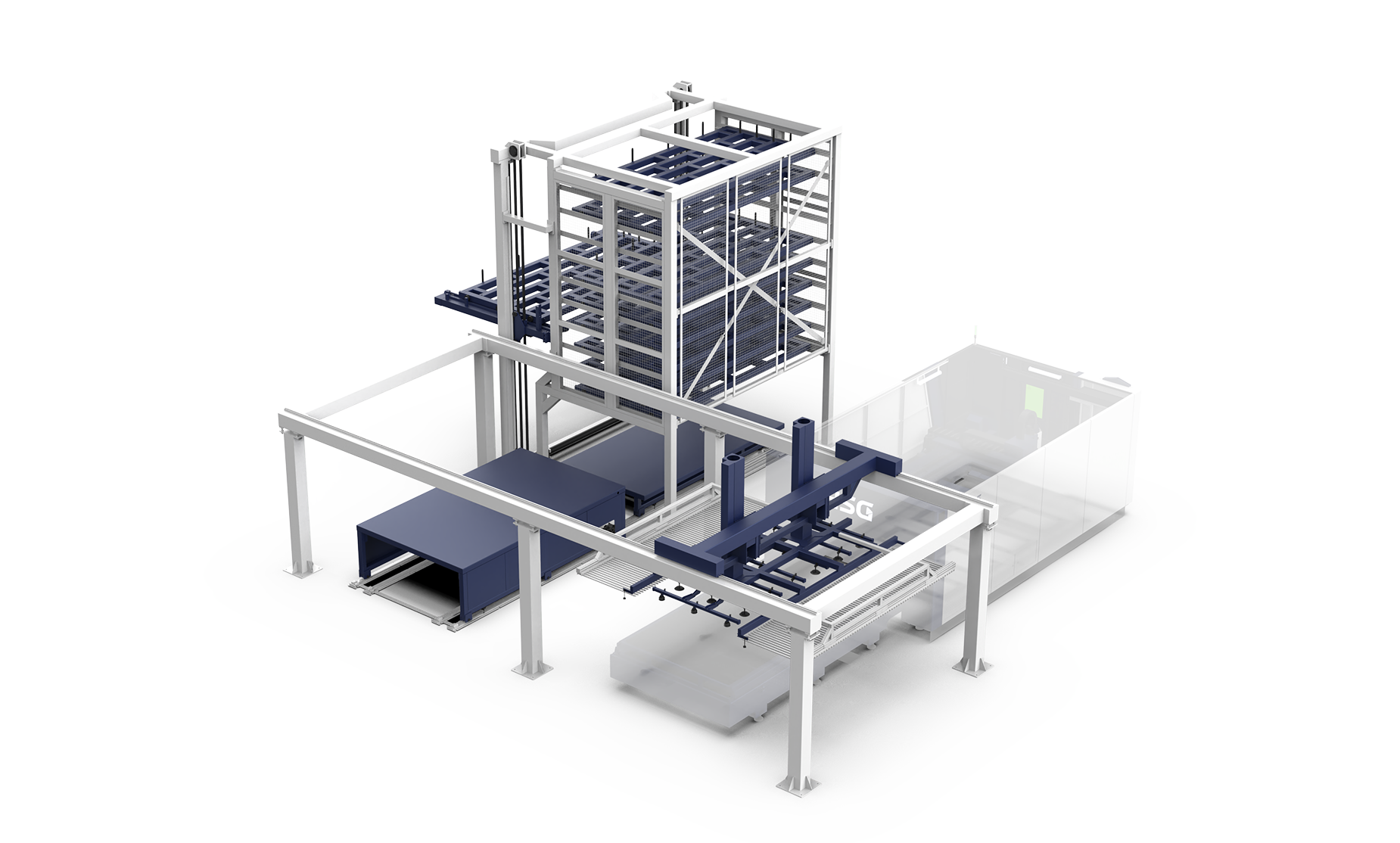

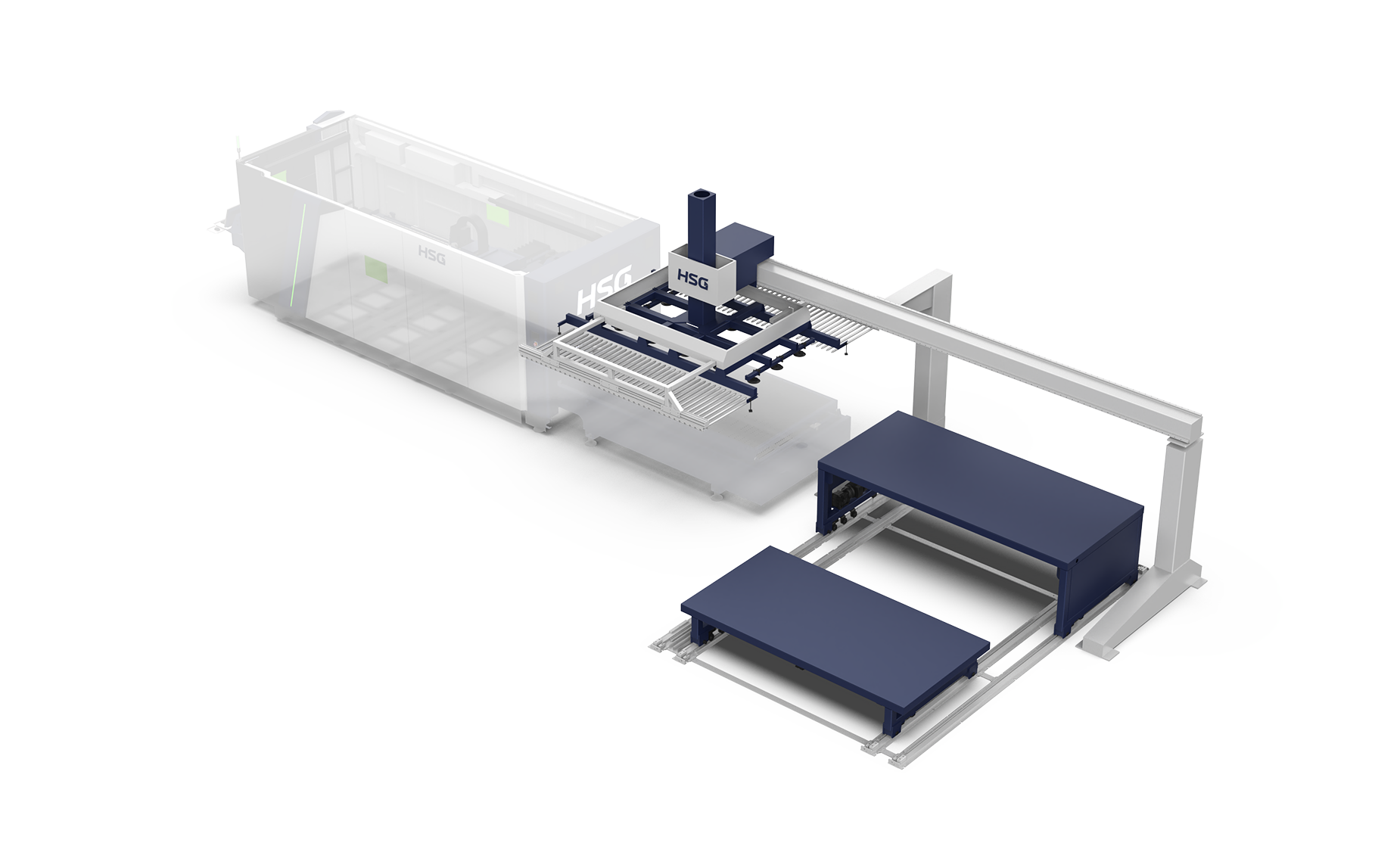

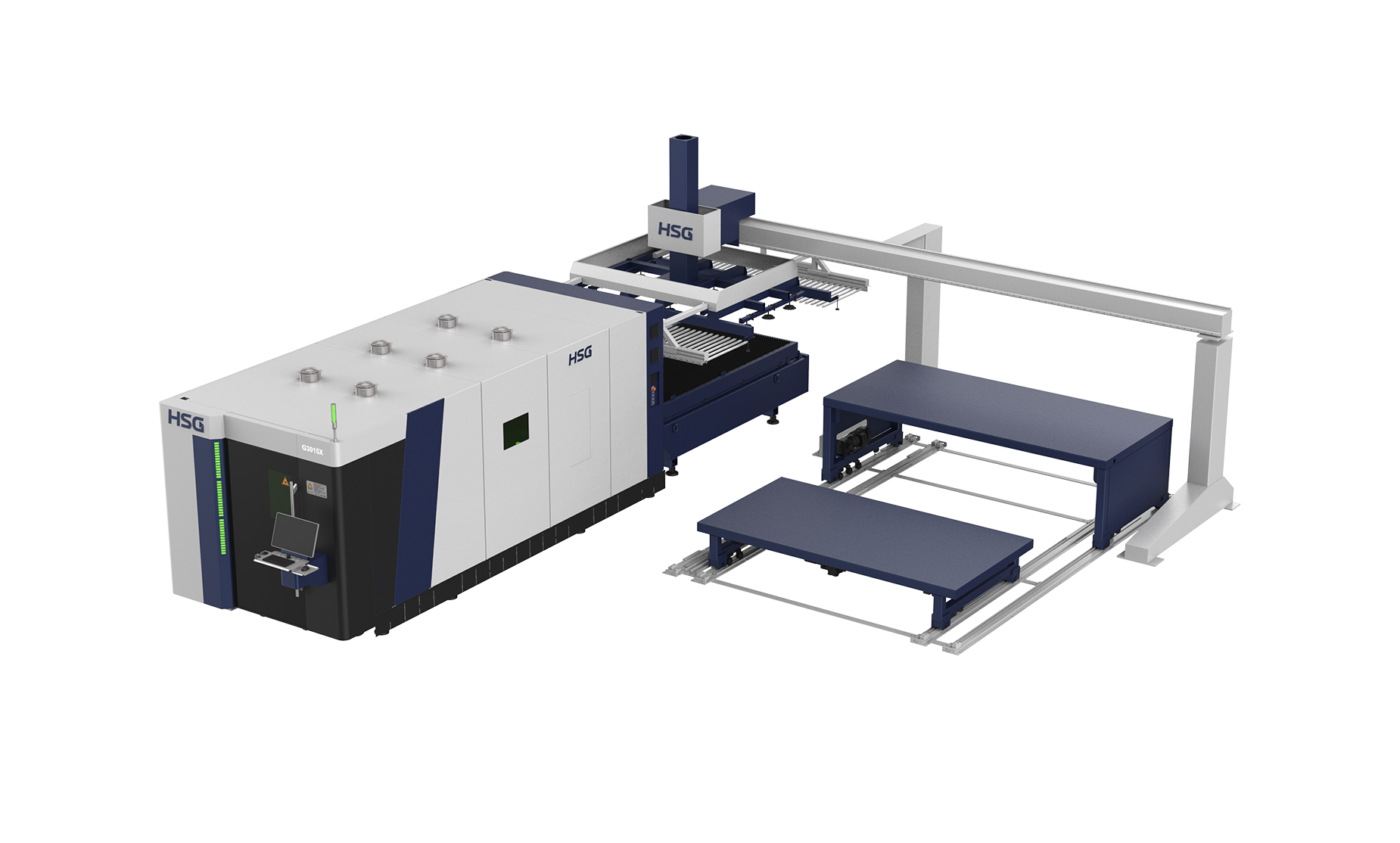

ALG Pro

Premium Automatic Loading & Unloading System

Optimal Use of Space Due to Compact Design

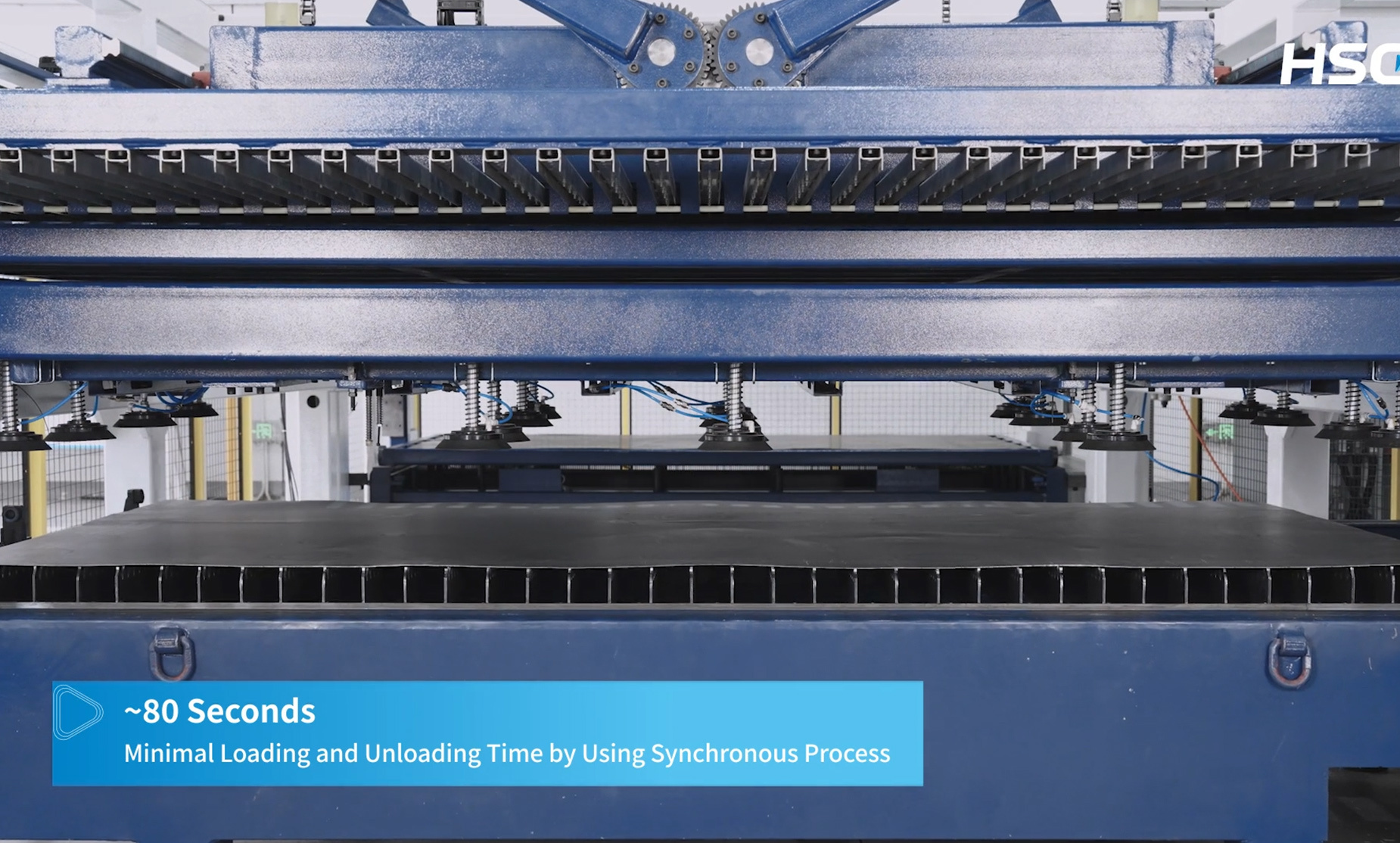

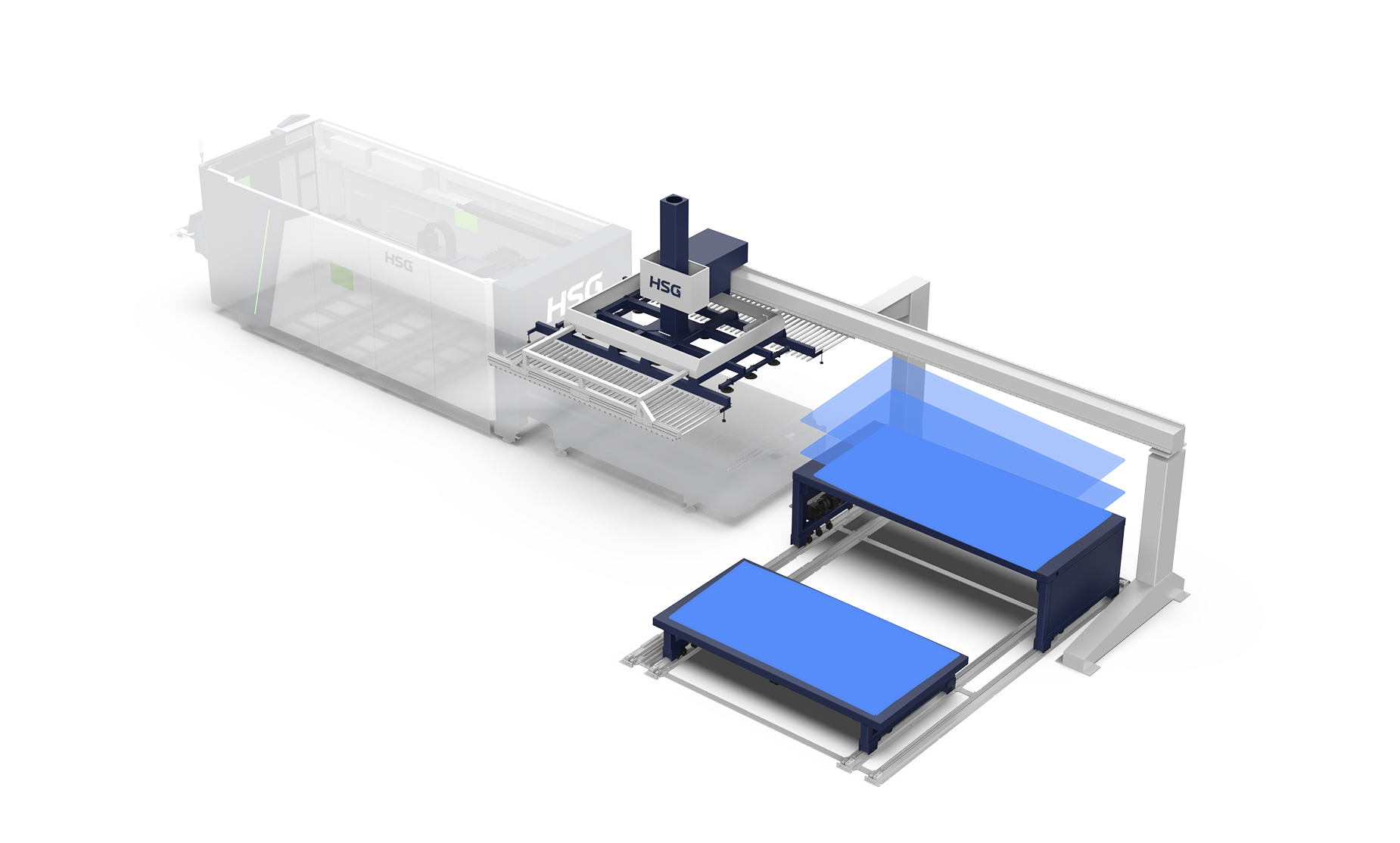

Boost Your Productivity with Time Saving

Short cycle times thanks to synchronous loader,a complete loading / unloading cycle only takes 80 seconds.

Sheet layering Thickness Measurement

Reliability is the Key for Automation

The key to automation systems is reliability. Smart sensors ensure long-term stable operation, boosting both production efficiency and profitability.

HSG ALG Pro Technical Specifications

| Model | ALG Pro 3015 |

|

Structure

|

Gantry

|

|

Max.Loading Sheet Size

|

3048×1524 mm (10' x 5') |

|

Min. Sheet Size: Loading/Unloading

|

1000×1000 mm (3.28' x 3.28')

|

|

Sheet Thickness Range

|

0.8mm - 16mm |

|

Max. Sheet Weight for Loading/Unloading

|

600kg (1323 lbs) |

|

Max. Loading Weight of the Finished Part Pallets

|

3000kg (6613 lbs) |

|

Incl

|

Light curtain and fence / Thin sheet separation |

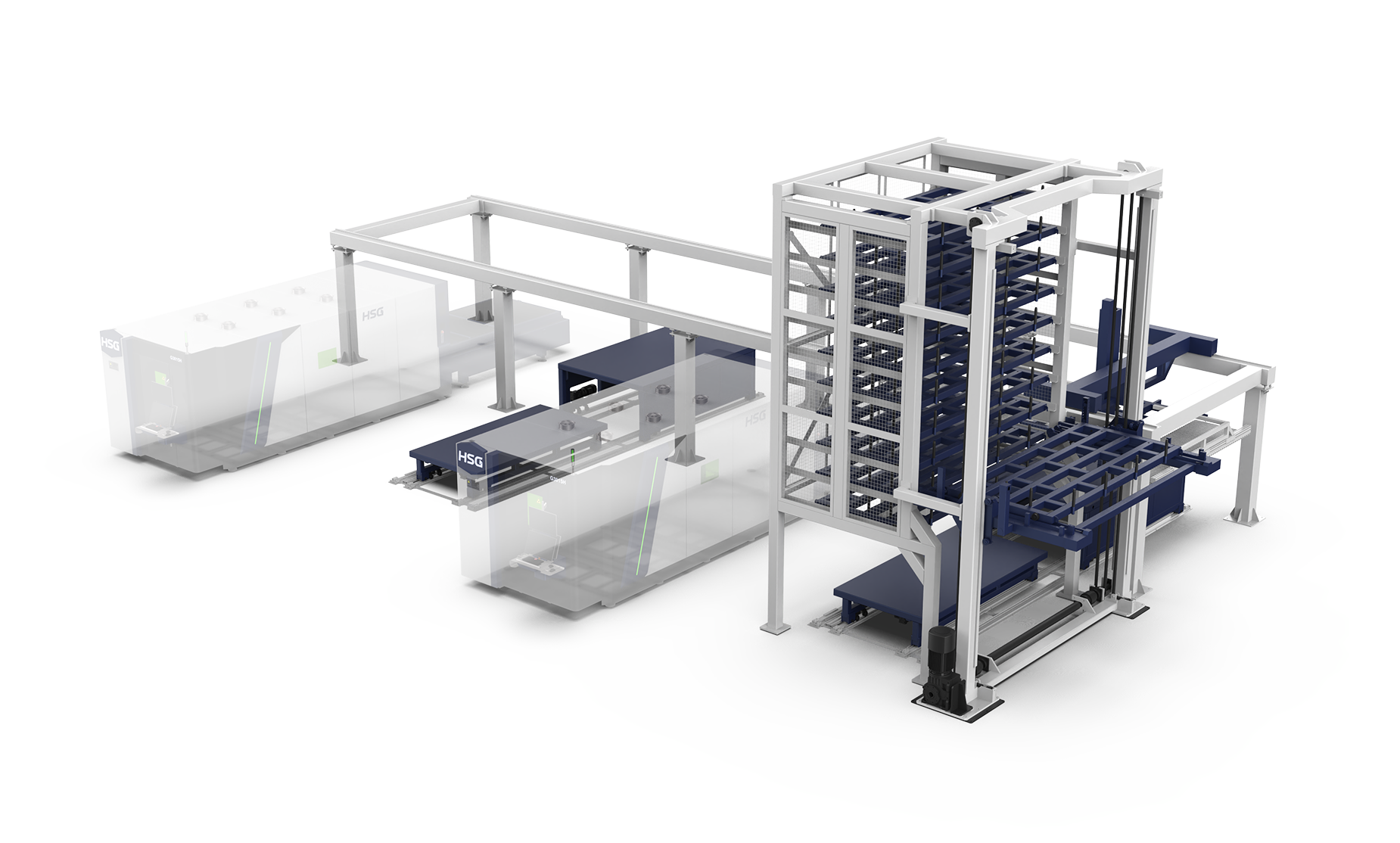

Store

Tower Storage System for Sheets

Scientific and compact board storage solution

Automated Processing for a More Scientific Approach to Production

Based on the production plan, the system automatically schedules operations and supports unmanned cutting cycles. This reduces manual labor and minimizes errors, ensuring higher efficiency and accuracy.

Modular Expansion with Support for One-to-many Operations

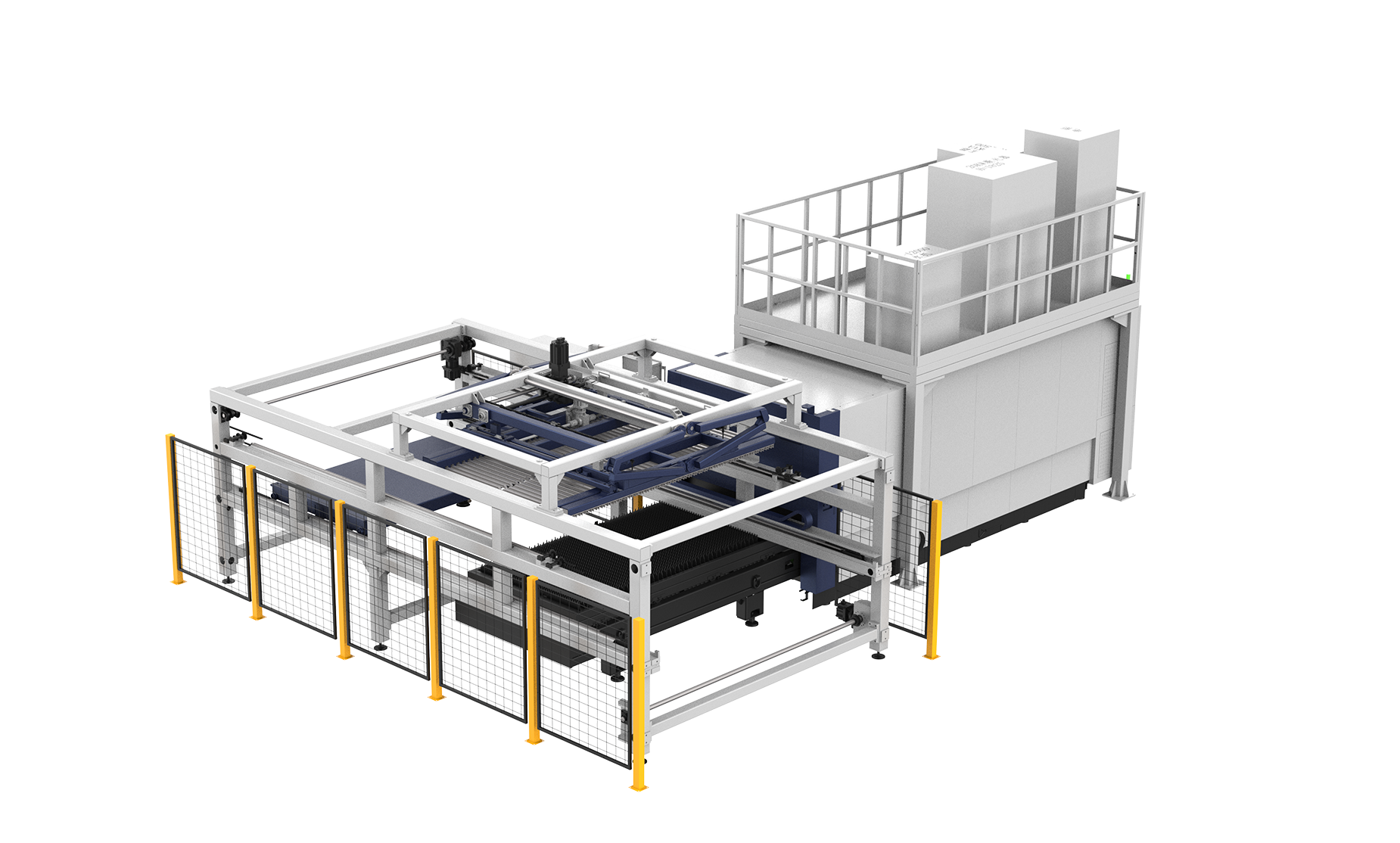

ALG

Automatic Loading & Unloading System

Automatic Operations, Ensure Safe Production

Achieve material loading automatically for saving time and improving productivity.

Sheet layering Thickness Measurement

Measure thickness of sheets automatically for accurate processing.

HSG ALG Technical Specifications

| Model | ALG3015-400 | ALG4020-800 |

|

Compatible Model Series

|

G3015X,G3015H

|

G4020X,G4020H

|

|

Max Loading Sheet Size

|

3000mm×1500mm | 4000mm×2000mm |

|

Each Sheet Thickness Range

|

1-12mm

|

1-12mm

|

|

Max Loading Weight

|

400kg | 800kg |

REQUEST A QUOTE OR FREE SAMPLE