Technology

Leading Innovator in the Laser Cutting Industry

Over the past 19 years, HSG has evolved from a startup into a leading innovator in the laser cutting industry. Through continuous independent research and development, HSG has successfully overcome numerous challenges and achieved significant breakthroughs. As of February 2025, HSG has obtained 442 patents.

With 3 R&D centers, 9 laboratories, and 5 industry-university research bases globally, HSG collaborates closely with top universities to explore cutting-edge laser optical applications. This partnership allows us to enhance the precision and efficiency of laser processing, enabling HSG to offer customers more reliable and advanced laser technology solutions.

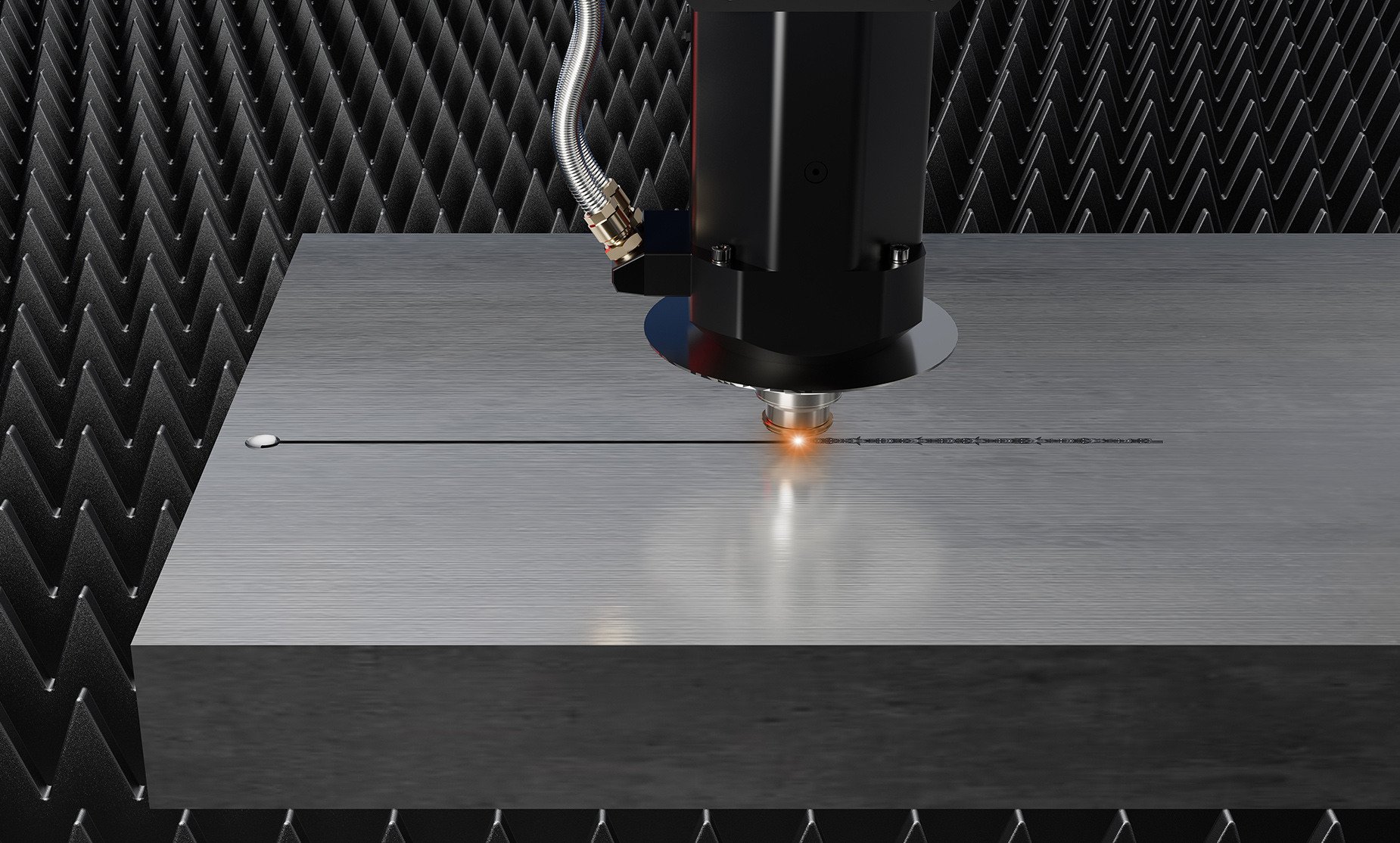

HSG Self-Developed P Series Cutting Head

HSG has partnered with a highly experienced Japanese optical technology research team to develop cutting-edge solutions for specific projects, addressing four major challenges in optical technology, optical path design, cooling systems, and motion control.

This collaboration has resulted in the introduction of the P series cutting head, which is renowned for its high-speed and stable cutting of thick sheets.

For HSG, innovation is a steadfast belief. The success of the P Series High Power Cutting Head stands as a testament to HSG's "From 0 to N" journey of innovation.

Advanced High-power Cutting Technology

The use of high-power technology enhances perforation speed and ensures superior edge quality, effectively reducing production costs while maintaining optimal cutting performance. This makes it an ideal solution for high-performance manufacturing.

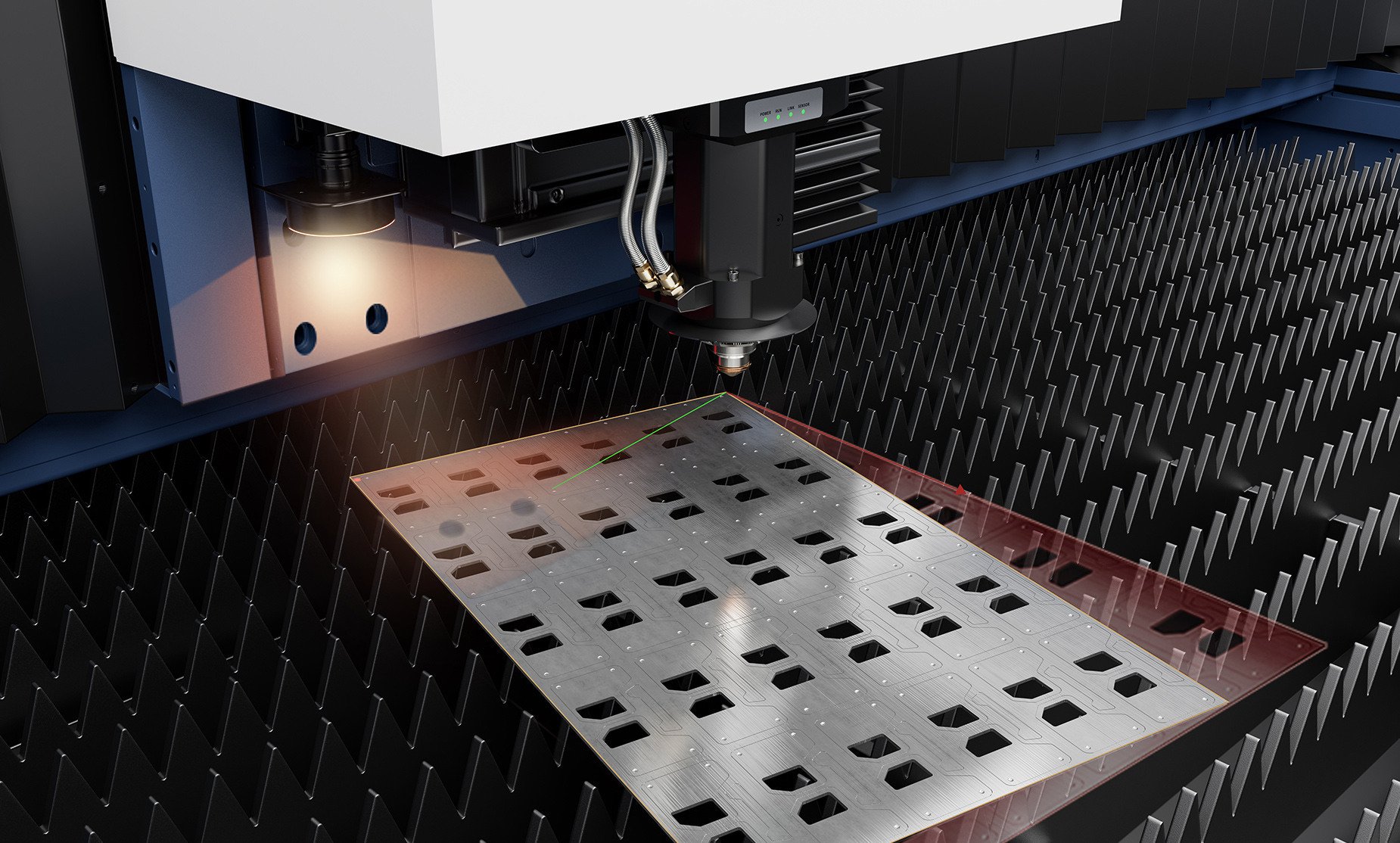

AR-powered Vision System to Enhance Processing Efficiency

Another key innovation in sheet metal cutting is the AR-powered visual system, which enables rapid edge detection and precise positioning through multiple visual sensors and AI-driven image stitching. This not only reduces the operator's workload but also enhances processing efficiency.

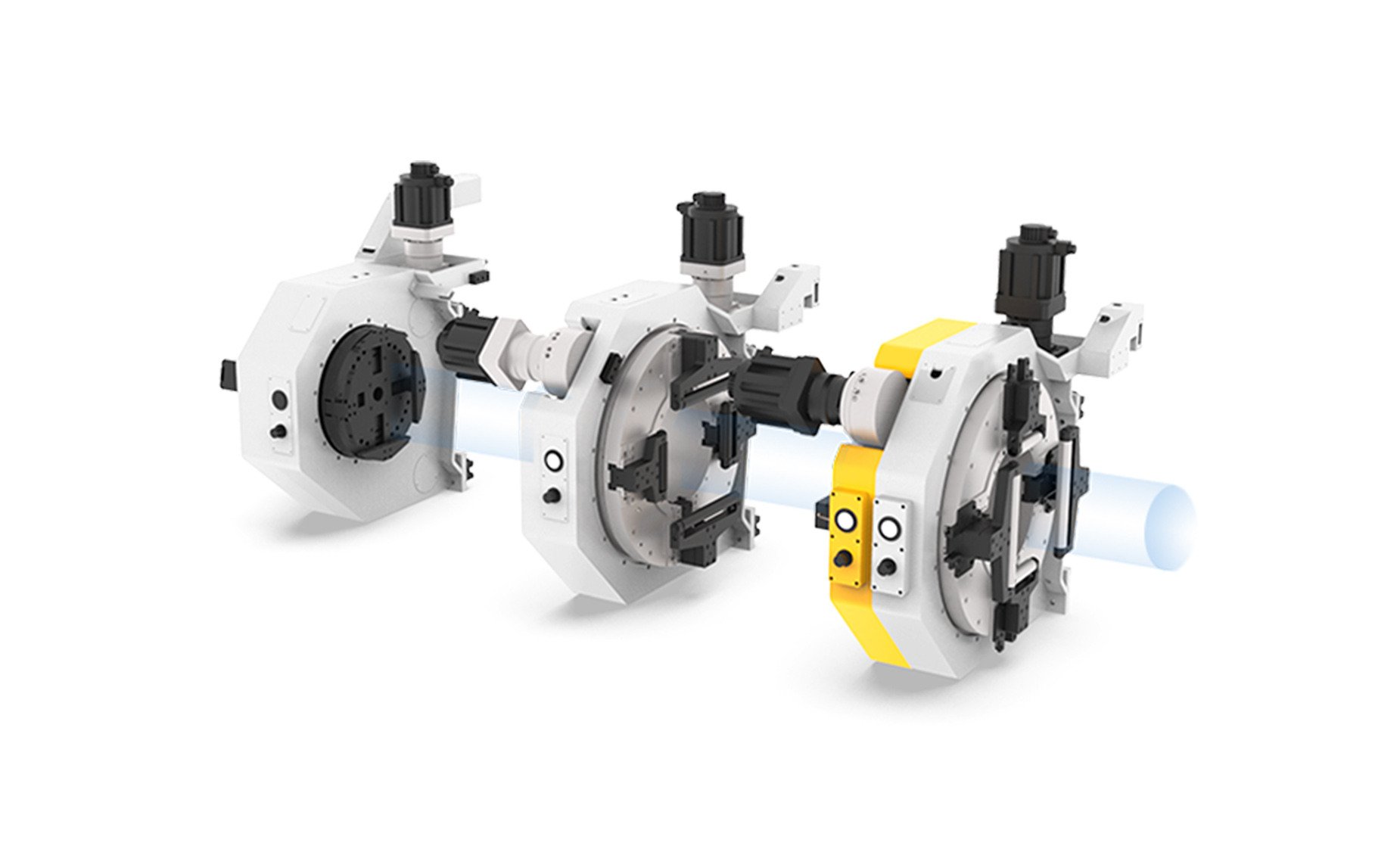

Leading Intelligent Digital Chuck Technology for Heavy-duty Tube

Since the launch of the TL500 in 2019, HSG has ushered in a new era in the field of heavy-duty tube cutting.

The "3+1 Twin-chucks" ingeniously combines the C3 and C4 chucks into one, capable of synchronous rotation and movement, while also allowing independent control of jaw opening and clamping. It provides both support and clamping functions simultaneously. The innovative chuck structure further increases the load-bearing capacity and processing length of the tubes.

In 2023, in the field of heavy-duty tube cutting machine technology, HSG Laser continuously broke the various records it held. After five years of preparation and innovation, the "4+1" Full-track Heavy Duty Tube Beveling Fiber Laser Cutting Machine TL730S has astonishingly emerged, redefining the landscape of HSG Laser cutting technology.

HSG’s DYNAMIC+ and 3D Cutting Technologies

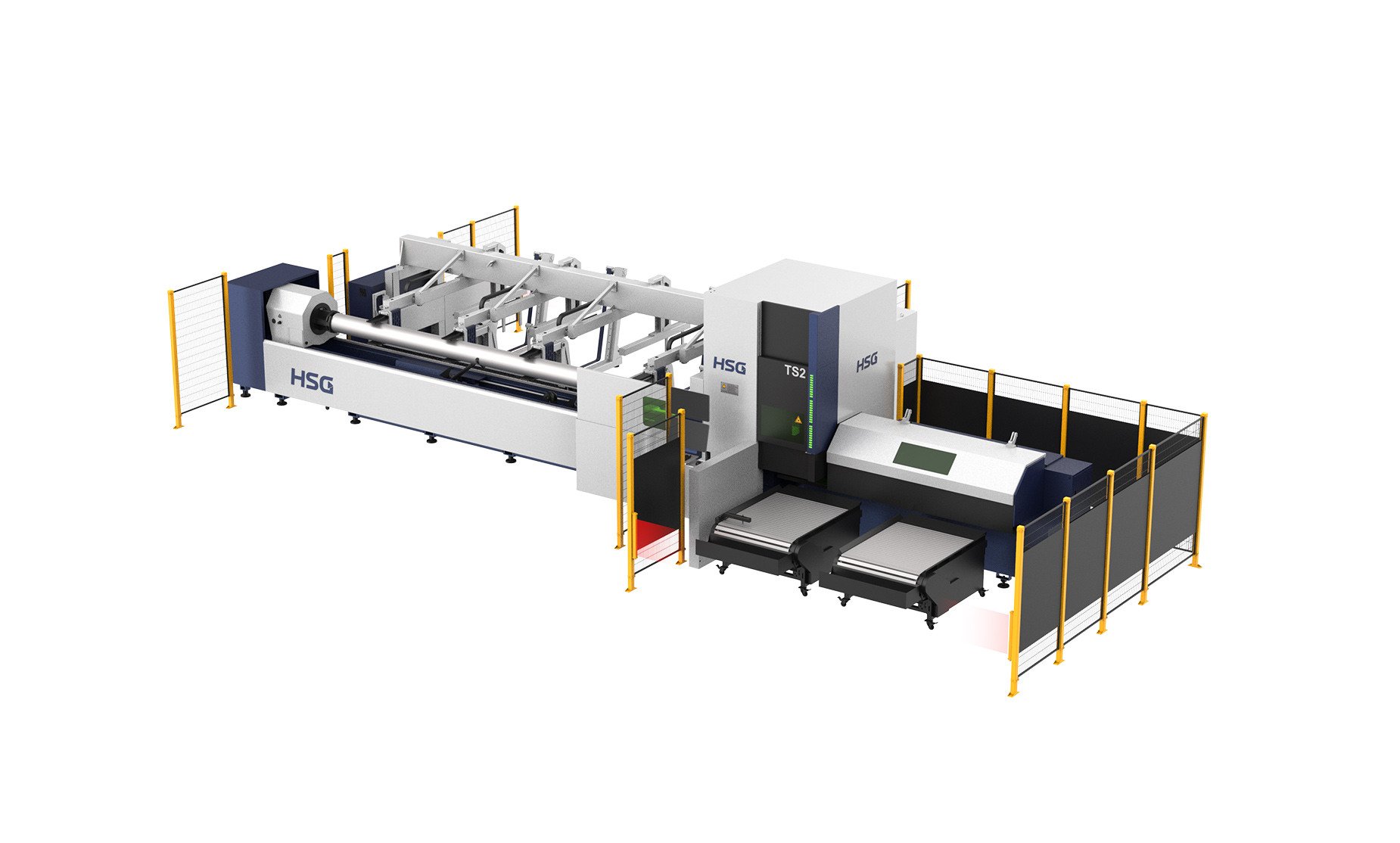

In 2025, HSG integrated Dynamics+ Cutting Technologies and 3D Cutting Technologies into the all new TS2 lasertube system. From structural steel components to high-precision tubing, the TS2 adapts effortlessly to any production requirement, delivering unmatched efficiency without compromising quality.

Before HSG's advancements, chuck functions were limited to basic mechanical clamping and fixing of tubes. HSG revolutionized the chuck by developing intelligent wireless digital chucks. These chucks can detect the claw status in real time, measure tube size, and wirelessly transmit data, ensuring precise and reliable tube clamping.

Pioneering 3D Five-Axis Laser Cutting Technology

HSG is one of the few domestic brands to have mastered 3D five-axis laser cutting technology. Our CELL3015 3D five-axis laser cutting machine is equipped with the self-developed LA5 intelligent cutting head, which features five-axis linkage. This cutting head enables 360° infinite rotation and a 135° swing, making it ideal for cutting complex 3D workpieces.

The All New Three-in-one Automation Solution

In 2025, HSG introduced the all new Store Pro automation system, which is a versatile three-in-one automation solution, combining unmanned night shifts, low-labor day shifts, and small-lot flow production to maximize efficiency and flexibility.

Its compact vertical design accommodates up to 10 storage positions per tower within a 4.4-meter(14.44') height, improving space utilization by over 70% compared to conventional storage solutions.

HSG’s latest technologies offer faster production cycles, optimized material usage, and intelligent automation, helping manufacturers scale operations while maintaining precision and profitability.

HSG has made a firm commitment tocontinuous innovation in these areas,even in theface of challenges.They collaborate with leadingpartners to drive innovation and propel thedevelopment of laser industry.

REQUEST A QUOTE OR FREE SAMPLE